Canning Overview

FNH-00705 View this publication in PDF form to print or download.

Canning heats food inside a jar that seals after air is driven from it. The heat destroys the microorganisms. During this process a partial vacuum is formed, which prevents other microorganisms from entering and re-contaminating the food.

Let’s go through the two canning methods used to preserve food in jars. Equipment to be used in this processing and the basic steps of each will be discussed as well.

Canning Processing Methods

Boiling Water Method

High-acid foods in jars can be processed when fully submerged in boiling water for the specified time for that product.

The pot, with a tight-fitting cover, must be large enough for the canning jars to be completely immersed and fully surrounded by boiling water, with the water covering the jars by at least 1 to 2 inches. The pot should be big enough to allow room for a rolling boil.

A metal basket or rack that fits in the pot is needed to hold the jars off the bottom of the pot. The jars must be held off the bottom so the heat can surround each jar and penetrate properly. This protects the jars from breakage. Keep the jars separate from each other.

Pressure Method

Because of bacteria, low-acid foods must be brought to 240°F, which is higher than the boiling point of water. To achieve this, low-acid foods must be processed in a pressure canner. This is a heavy pot with a lid that can be clamped or locked down to make a steam-tight container. The lid is fitted with a safety valve and a vent to allow air to escape. This vent may be closed with a petcock or a weighted gauge. The lid may have a dial pressure gauge.

Two types of pressure canners are available commercially: those with dial gauges and those with weighted gauges. Dial gauges must be checked periodically for accuracy. If the gauge is incorrect, the processing of canned goods will not be accurate and all bacteria, including botulism, may not be killed. Ask the Cooperative Extension office to check your dial gauge.

The vent or open petcock on your pressure canner allows steam to escape under a controlled pressure. If the vent or petcock should inadvertently become plugged, the safety valve is designed to pop, which releases pressure and prevents the sealed pot from exploding.

Because of the twin dangers of under-processed food and steam under high pressure, all parts of the pressure canner must be kept clean and in good working order. Make sure the vent/petcock and safety valve are free of obstructions. As long as the canner is clean and working well and foods are processed for the prescribed times and temperatures, pressure canning is a perfectly safe and efficient method for canning low-acid foods.

If, for any reason, the pressure should drop during processing, the processing time must be recounted from the beginning. Follow the manufacturer’s directions for your pressure canner.

Pressure saucepans, small pressure cookers and electric multicookers work similarly to pressure canners. However, to be used as a pressure canner, pressure cookers must be able to hold four quart jars on a rack with room for air to go over and around.

Containers

A heat-tempered, threaded, glass jar with a two-piece lid set is used for home canning.

Regular and wide-mouth glass jars come in sizes from 4 ounces to half-gallon and are made so they will seal well. The glass is tempered to withstand the heat of the steam pressure canner. The rims of the jars must be smooth, with no chips or cracks.

The two-piece lid set consists of a flat metal lid with a flanged edge. The underside of that lid has a rubber- like sealing compound. The other piece is a threaded metal screw band that fits over the rim of the jar to hold the lid in place. Follow the manufacturer’s directions when using this closure, since the sealing compounds for each brand are different.

Jars kept from commercially canned products used with new two-piece lids may be used to preserve high-acid food. However, these jars are made of thin glass for use on high-speed packing machines and will not withstand extreme temperatures in home pressure canning and freezing. There might be invisible nicks or scratches, which can cause jars to break, especially in the pressure canner.

Metal cans and lids may be used for home canning low-acid meat and fish. This is done in tapered 1 pound and 1 ½ pound size cans with matching lids. Alaska salmon cans have an enamel lining that is appropriate for low-acid food. A can sealer is necessary for this process. Use University of Alaska Cooperative Extension Service publications on canning in cans for information on canning these products.

Utensils helpful when home canning are a jar lifter, a jar funnel, and a thin plastic knife or spatula for filling jars. Knives, cutting board, measuring spoons and cups as well as other tools are needed for making the food to process.

Beginning to Can

Read through recent research-tested recipes before beginning to can. Decide in advance what equipment you will need. Assemble all equipment and check for cleanliness and working order before starting to can. This helps avoid searching for a needed item during the critical time when the food is being prepared and processed.

Wash jars and lids in hot, soapy water and rinse well. Don’t use wire brushes, steel wool or abrasive cleaners for cleaning jars; they are likely to damage the glass. Leave the jars in hot water until they are ready to use. If a dishwasher is used, leave the jars in the machine until you are ready to use them, or keep them in hot water heating in the canner.

Jars that are to be processed for less than 10 minutes should be sterilized. Sterilize jars by submerging them in water; boil for 10 minutes.

Choose food to can. Consider how much will be available. Fruits and vegetables are best when ready to harvest, but rarely do they all ripen on the same day. Moose may be ready to can immediately after cut. Other points to consider:

- Pieces should be same size so the heat will penetrate evenly.

- Product should be completely ripe.

- Don’t use blemished produce. It may produce a product of very low quality. Carefully trim small blemishes away.

- Wash well.

Follow the recipe instructions to prepare the food. It may be hot packed, which indicates par-cooking, or raw packed, which is placing food firmly in the jar without crushing it. After the food is placed in the jar, liquid is added to cover it.

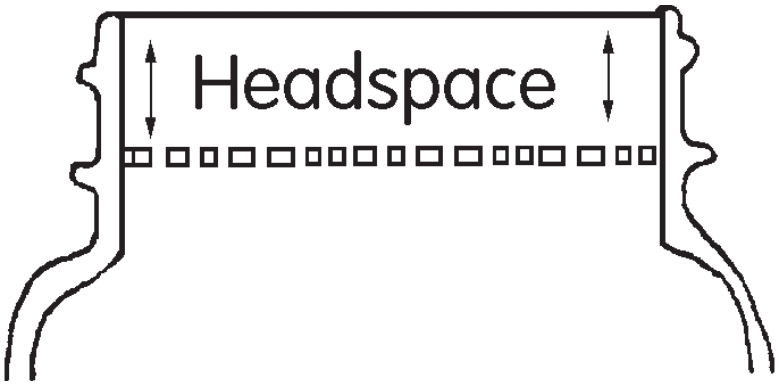

Measure headspace carefully. This is the space between the top of the food/liquid and the rim of the jar.

The type of food and container makes a difference in the amount of headspace to use. Use current, research-based recipes for processing directions and headspace for each food. If jars are too full, contents may boil out when processed. This may cause bits to be caught in the sealing compound, preventing a seal. If there is too much headspace, all of the air may not be pushed out through processing. A tight vacuum seal may not occur. Too much air left inside the jar may cause the food to discolor.

Remove air bubbles by running a plastic knife or rubber spatula between the food and the jar. Don’t use a table knife as it may damage the jar.

Wipe jar tops with a clean, damp cloth. Particles of food that remain can prevent a tight seal.

Center the lid, gasket down, onto the cleaned rim of the jar. Add the metal screw band over the flat lid until you feel the slight resistance. Then re-position your hand and tighten the screw band 1 to 1 ½ inches more. The band should be just tight enough to hold the lid in place, but loose enough to allow the air to vent out of the jar during processing to become a tight vacuum seal.

Process immediately after jars are closed to minimize the possibility of microorganisms multiplying in the food. Process foods for the exact time given in the recipes. Too little time may result in the food spoiling; too much time will cause the food to be over-cooked. Follow the steps in processing for the method being used.

Boiling Water Canner. Immerse the hot jars, filled with hot or raw packed food, lids on, in simmering water: 180°F for hot pack, 140°F for raw pack, onto the rack in the canner. Cover the pot and turn the heat to high. Start the processing time when the rolling boil begins. Boil gently but steadily for the time required. Add boiling water if needed to keep tops of jars covered by 1 to 2 inches of water. Remove jars, upright, with a jar lifter, as soon as the processing time is completed. Place on a rack on the counter until cool.

Pressure Canner. With 2 to 3 inches of hot water in canner, put filled jars with lids on the rack in canner. Place so steam will flow freely around each jar. Fasten canner lid securely. Exhaust canner; leave vent (petcock) open and allow steam to escape for 10 minutes. Close vent or place a counterweight or weighted gauge on the steam valve. When the dial gauge or weighted gauge registers the recommended pressure, start the processing time. Regulate the heat under the canner to maintain a steady correct pressure. Follow manufacturer’s directions for using the canner and how a weighted gauge indicates correct pressure. When processing time is complete, turn off the heat. Let sit until pressure drops to zero. Remove weight or open the petcock. Let sit 10 minutes more. After this 10 minutes, unfasten the lid and lift it away from you as it is removed. Remove jars with a jar lifter, straight up, and place on a wire rack or thick towel until cool.

After Canning

Cool the jars at room temperature for 12 to 24 hours. Keep out of drafts to avoid breakage. Most two-piece vacuum lids “ping” as the jar seals.

If food has boiled out of the tops of the jars during processing, do not attempt to readjust the lids (i.e., tighten the ring) since this will probably break the seal. After the jars have cooled, wipe any residue away. Use the food in these jars quickly to avoid discoloration.

After thoroughly cooled, check to see if a proper seal has occurred. Push down in the center of the lid. If it does not push down, it is sealed. Remove screwbands from jar and wipe jar with a damp cloth to remove any residue. Label each jar with date, food and method used. Jars are safe to store without screwbands.

Seal failure. If the lid pushes down, then springs up, the jar is not sealed. Food must be reprocessed, refrigerated and used within three to five days, or frozen for later use.

If for any reason the jar has failed to seal, repack the jar and use a new lid, reprocessing the full length of time called for in the recipe.

Store canned foods in a cool, dry, dark place. Light hastens oxidation and destroys certain vitamins; also, foods may fade in color. A cool place is necessary to slow down the loss of nutrients. Damp storage can cause metal lids and closures to corrode or rust and endanger the seal.

Food that has been properly canned will keep indefinitely, but after a year some chemical changes tend to occur. This may result in a lower-quality product. Properly canned food has a recommended shelf life of approximately one year.

Signs of Spoilage

Before tasting, check the food for signs of spoilage. Indications that food has spoiled are:

- Broken seal

- Seepage

- Mold

- Gassiness

- Sliminess

- Cloudiness

- Disagreeable odors

- Spurting liquid when jar is opened

If it doesn’t look or smell right, do not use it.

Adjustments for Altitude

Time must be increased when a boiling-water bath is used at an altitude of 1,000 feet or more. For each 1,000 feet above sea level, add 2 minutes to processing time if the time called for is 20 minutes or less. If time called for is more than 20 minutes, add 4 minutes for each 1,000 feet.

When a pressure canner is used at an altitude of 2,000 feet or more, pressure must be increased by 1 pound for each 2,000 feet of altitude. Check with your Cooperative Extension agent for recommendations.

Steps to Successful Canning

- Know and understand the basics of canning.

- Check all equipment. It should be clean and in good working order; jars not chipped or cracked.

- Select only the best product. Wash and rinse thoroughly.

- Follow research-based recipe closely.

- Pack food in jars; leave recommended headspace. Remove air bubbles. Wipe top and threads of jar.

- Attach closures. Follow manufacturer’s instruction.

- Process using proper method and length of time.

- When processing time is completed, remove jars and place on cloth or rack, out of drafts and with space between.

- After 12 to 24 hours, test seals.

- Store in cool, dry, dark place.

References

USDA Complete Guide to Home Canning. Online version: https://nchfp.uga.edu/resources/category/usda-guide. Print version: https://mdc.itap.purdue.edu/item.asp?item_number=AIG-539#.VWTLiZRdWrY.

So Easy to Preserve. University of Georgia Cooperative Extension: www.uga.edu/setp.

Ball Blue Book. Ball Corporation, Consumer Products Division, Consumer Affairs, 345 S. High, Muncie, IN 47305-2326.

Julie Cascio, Extension Faculty, Health, Home and Family Development. Originally written by Roxie Rodgers Dinstel, former Extension Faculty, Health, Home and Family Development.

Revised October 2024