Small-Scale Irrigation Options

FGV-00646 View this publication in PDF form to print or download.

Throughout Alaska, it can be highly beneficial to irrigate crops to supplement the moisture they receive from natural rainfall. Warm Alaska weather is often accompanied by long periods of drought, and when it does rain, the moisture accumulation is often inadequate to keep crops producing optimally. Many locations throughout the state also have fairly thin layers of soil for growing plants, and the underlying bedrock or gravel allows the water to drain, making it unavailable for crop use. With these difficult conditions, most crops will greatly increase productivity and quality if watered appropriately. In general, vegetable crops need about 1 inch per week and turf thrives with ¾ inch per week, either from natural rainfall or from supplemental watering

A series of irrigation studies at the Matanuska Experiment Farm were conducted to determine the importance of irrigation for increasing crop yield. In a comparison of potato yields for plots that were watered versus adjacent plots that were not, the advantage of irrigation became clear. For many varieties, irrigated yields were 40 percent higher than nonirrigated yields. Furthermore, many crops (such as potatoes) have critical periods in their development when drought stress can dramatically decrease crop quality. Having a good watering system in place can help keep the crop healthy, and in turf systems, irrigation helps the grass “crop” recover from playing damage or high-traffic impacts.

Beyond providing water to plants, irrigation systems can be beneficial in other ways. Overhead sprinklers have long been used as a form of protection when an unexpected frost threatens the crop. The sprinklers are turned on, and as the water freezes on the plant, it releases heat, which can be enough to keep the plant itself from freezing. The water from irrigation also can be used to hold dry, bare soil when a windstorm comes, since moist soil is much more resistant to wind erosion.

There are numerous irrigation systems to choose from, ranging from a simple garden hose with the appropriate attachment to dedicated irrigation equipment. Frequently, a decision is made based on the amount of time available for watering and the cost of the appropriate dedicated system. For most situations, a series of garden hoses requires the least amount of capital investment, but there will be a significant amount of labor invested in watering. The mechanized irrigation equipment discussed later in this publication may represent a significant investment, but it will also free up labor to focus on other objectives.

Methods of measuring rainfall and irrigation

The simplest method of measuring rainfall and irrigation is to use a commercial rain gauge. These plastic instruments are placed away from the foliage and close to the ground to measure the amount of water that hits the ground.

When determining the watering pattern, place a series of short-sided (tuna fish type) cans in a grid. After the irrigation has been applied, measure the depth of the water in the can with a ruler. It is important to use a straight-sided can rather than a bowl-type container.

Garden Hoses

Garden hoses are the simplest way to irrigate, and they provide a great beginning for many operations. Garden hose systems are designed to operate under standard household water pressures and flow rates. There are six common types of garden hose watering systems: hand held hoses, soaker hoses, oscillating sprinklers, cyclone sprinklers, moving water nozzles and impact sprinklers.

Hand held hose: A simple garden hose is perfect for a small area or individual plants. Although it can take a lot of time to individually water each plant when there are many of them, with this system the grower can give each plant the ideal amount of water for it to produce optimally.

Hose nozzles: When watering with a hand-held garden hose, it is most beneficial to the plants to attach a nozzle as a way to direct water flow and minimize damage to the foliage. There are two main types of hose nozzles that are useful for watering plants: breaker nozzles and misting nozzles.

The breaker nozzle (also called a water rose) is an attachment that is very similar to a shower head in the way it releases water from the hose. The water pressure is lowered as it is forced through many small holes on the nozzle, which essentially turns the garden hose into a watering can with an endless supply of water. The breaker nozzle provides a large amount of water at relatively low pressure to the plants with minimal damage to the soil and foliage.

Misting nozzles are similar to breaker nozzles; however, they have fewer holes in the nozzle and the holes are much smaller. The water is pushed through these tiny holes, creating a mist that is perfect for watering newly seeded flats and other locations where strong water pressure could wash away or damage seeds and seedlings.

Adjustable nozzles are equipped with a variety of settings (from jet to shower), so that water flow can be carefully controlled. The most important thing to keep in mind when choosing a setting or a nozzle for the hand-held garden hose is how to best minimize damage to plant foliage during watering, while also providing the needed amount of irrigation to the plants.

Soaker hose: Another basic option for irrigation is the soaker hose, which is basically a section of hose that is perforated with many tiny holes. The water gently trickles out of the hose onto the soil, watering the area around it. A soaker hose is generally 10 to 25 feet long and hooks up to a regular garden hose for water access. The main drawback to this type of irrigation is that the water may come out at a heavier rate at the beginning of the hose and a lower rate at the end of the hose.

Oscillating sprinkler: Oscillating sprinklers are generally used as lawn sprinklers or for small gardens. They usually consist of a moving perforated bar on a stationary base, and they spray water in long streams through the perforations while moving back and forth. These sprinklers apply water around the sprinkler head in a rectangular pattern ranging from 300 to 1,500 square feet. The application rate is determined by water pressure and hose diameter and length. The water distribution pattern gets more uniform as the sprinkler increases in quality. Oscillating sprinklers are easy to move around, limited only by the length of the hose they are attached to.

Cyclone sprinkler: The cyclone sprinkler is another type of sprinkler that attaches directly to a hose. It consists of at least two perforated, curved arms that have the ability to spin and are attached to a central frame. As the water pushes through the sprinkler, it acts like a jet, causing the sprinkler arms to spin around to deliver water in a circular pattern. A cyclone sprinkler generally doesn’t cover as much area as an oscillating sprinkler. Like the oscillating sprinklers, the distance covered by a cyclone sprinkler is determined by water pressure and hose diameter and length.

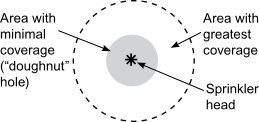

Impact sprinkler: An impact sprinkler consists of a metal head that rotates around a stationary supply pipe. The stream of water hits a deflector vane on the sprinkler head, causing the head to swing out of the water stream. Gravity, or a slight spring, causes the sprinkler vane to swing back in and impact the head. When the deflector impacts the stationary portion of the sprinkler head, it causes it to rotate slightly. The stream of water pushes the deflector out and the cycle repeats. The sprinkler head shoots out a stream of water 20 to 40 feet, depending on water pressure, while traveling slowly in a circle or portion of a circle. Some models deliver water at consistent rates at all points in the irrigated circle, while many others deliver more water farther away from the sprinkler, so the area is watered in a “doughnut” pattern. Impact sprinklers should be positioned so that the circles of watering overlap and compensate for the doughnut hole in the pattern (see diagram on page 5). Some sprinkler heads have adjustments that allow them to water an arc rather than a full circle, which is useful for corners and edges of the planting area, as well as near walkways and roads. The watering pattern and distribution of specific sprinklers should be verified with rain gauges.

Flow meters and control valves

For certain needs it may be necessary to measure the amount of water used.

Simple flow meters are available to measure how much water passed through the line since it was reset to zero.

Volumetric shut-off valves go the next step. They are set to a desired volume of water and they shut off automatically when that volume has been reached.

Moving water nozzle (lawn tractors): These devices are often shaped like a small tractor, with larger wheels on the back and smaller, guide wheels on the front. The hose connects to the back of the tractor, while the tractor straddles the hose and the guide wheels keep the tractor on course. The water pressure rotates the sprinkler arms, which are generally cyclone type, and provides enough pressure to move the tractor along the hose. The hose does not need to be laid out in a straight line or any normal pattern; it should simply be laid out in any way that allows the sprinkler to water the intended area. Some models will even quit by themselves once the entire area has been watered.

Drip Systems

One style of drip system has fine tubing (¹⁄8 to ¼ inch) that comes from the mainline and terminates in an emitter that is placed in the container or in the root zone of the specific plant to be watered. The emitters are available in various capacities and usually deliver ½ to 3 gallons per hour. The supply line does not come with holes in it for inserting the fine tubing; instead, the user can make them at exactly the location needed for the plant. These systems are best used when only specific zones or containers should be watered.

Drip tape is a continuous plastic tape with a series of holes in it to water the root zones of plants. While drip tape and soaker hose systems are similar, there are several important differences. Where a soaker hose has a continuous series of perforations, drip tape has perforations in very discrete locations, every 4, 6, 8 or even 12 inches, depending on the style. Many drip systems operate on water pressure that is lower than normal household water pressure and will need a pressure reducer fitting, while other drip systems are designed to operate at standard household water pressures. Drip systems can be used along much longer planting areas than soaker hoses (several hundred feet versus 15 to 50 feet). For more information on drip systems, see UAF Cooperative Extension publication FGV-00648, Trickle Irrigation for Alaska Gardens.

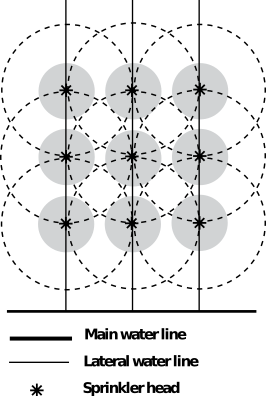

Hand Line and Solid Set Systems

Hand line systems are easily movable and are generally repositioned throughout the season to provide irrigation for various crops. Solid set systems are more stationary, although they are often assembled from the same materials as hand line systems. Both systems consist of a series of pipes (laterals) that transport water to sprinkler nozzles on top of risers of varying heights. The pipes are usually 20- to 30-foot sections of aluminum, usually 2 to 4 inches in diameter, and connect temporarily to each other with aluminum joints and some sort of latching system. The risers (smaller pipes going from the lines to the actual nozzles) are located at the female connection of each pipe segment. Riser heights are available from 1 to 6 feet high and the appropriate length is chosen so the sprinkler head will always be above the canopy of the crop. Most vegetable crops require only a 2- to 3-foot riser.

Water is brought from the source to the field through the mainline, which consists of sections of larger diameter pipe without risers and nozzles. Each of the lateral lines connects to the mainline in order to supply water to the sprinklers. The diameter of the mainline pipe is usually larger than the diameter of the lateral lines — unless the area to be irrigated is very close to the main water source — since larger-diameter pipe moves water more efficiently than smaller pipe. Finally, the lateral lines connected to the main line are controlled by valves, which turn the water flow on or off. The number of lines that can be operated at the same time is determined by pump capacity, the number of sprinkler nozzles attached to the lines and the capacity of the mainline.

Most operations do not have enough pipe (or a water source) to irrigate an entire production area, so the hand line must be moved. Generally, a portion of the field will be irrigated, then after adequate water has been applied, the lateral irrigation lines will be disconnected from the mainline and moved to a new section of the field, where they are reconnected to other valves in the mainline. Although moving the lines can be done by one individual, it is much more efficient to move the pipe with two or more people.

If the operation has enough irrigation lines to cover the entire field for the season, the system is said to be “solid set.”

Watering pattern of impact sprinkler

Some sprinklers deliver more water farther away from the sprinkler, so the area is watered in a “doughnut” pattern. Impact sprinklers should be positioned so that the circles of watering overlap and compensate for the doughnut hole in the pattern (see below).

A relatively new type of nozzles — rotating nozzles such as the Senniger Wobbler series and the Nelson Rotator series — are rapidly making inroads into the impact sprinkler market. They are much simpler mechanisms and are considerably less expensive than quality impact sprinkler heads. They operate well at lower water pressures, thus making them ideal for irrigation systems with smaller irrigation pumps (or longer distances from the pump). Their coverage pattern is less of a “doughnut” shape than most impact sprinklers, so overlapping positioning is less of a factor. The larger droplets thrown out by the rotating nozzles lose less water to evaporation and are less affected by shifts in wind direction.

The convenience of solid set systems is that they allow larger areas to be irrigated

by simply starting the pump and opening selected valves. Since the system is built

from moveable parts, the field can be tilled and planted without the irrigation system

in the way. Once field operations are completed, the irrigation lines are set up.

When properly designed and laid out, solid set systems provide uniform coverage across

the field. Once the season is over, the pipe is easily removed from the field and

stored for the next year.

The convenience of solid set systems is that they allow larger areas to be irrigated

by simply starting the pump and opening selected valves. Since the system is built

from moveable parts, the field can be tilled and planted without the irrigation system

in the way. Once field operations are completed, the irrigation lines are set up.

When properly designed and laid out, solid set systems provide uniform coverage across

the field. Once the season is over, the pipe is easily removed from the field and

stored for the next year.

The inconveniences of solid set irrigation include setting up the system every season and having numerous pipes going across the field. When using a tractor or rototiller in the field, whether for midseason cultivation or harvest, many of the pipes must be moved. Also, since the pipe connections every 30 feet are temporary, the lines may come apart or the gaskets may fail, so the lines often need attention more frequently than more permanent systems or hoses.

Achieving proper coverage is a matter of matching the proper sprinkler head to the pipe system. The most common impact sprinkler gives a doughnut-shaped pattern of water, with the riser and nozzle at the center of the doughnut, so it depends on the adjacent sprinklers to water the area directly underneath the sprinkler head. Rotating multistream nozzles (i.e., rotators and wobblers, etc.) are being evaluated on hand-line risers. These systems offer uniform coverage along with larger water droplet sizes, which can minimize evaporation and the influence of wind on the irrigation pattern. It is important to work with the system vendor in order to determine proper riser spacing and sprinkler head choices.

Traveling Gun Systems

Traveling gun systems come in many sizes. Small ones are suited for irrigating sports fields and other similar sized areas while larger models can irrigate a 300-foot swath well over 1,000 feet long. Numerous models are ideal for 1- to 5-acre operations.

Traveling gun systems consist of a single large nozzle (or gun) mounted on a wheeled cart, a supply line of 1- to 5-inch flexible hose and a winding reel. A cable-tow traveling gun system uses a cable to draw the gun cart and nozzle through the field while the water supply hose is dragged behind it. The cable is fixed to the winding reel, which is powered by a water motor or by a separate motor. As the cable is reeled in, the sprinkler is pulled through the field, watering the entire swath. A hose-pull traveling gun system is similar to the cable-pull system, but the gun cart and nozzle are pulled through the field by the hard polyethylene hose that supplies the water. If several fields of various sizes are to be irrigated, there are advantages to the hose-pull gun systems since they are easier to prepare for transport and the hose can be pulled out to exactly the length needed.

The amount of water delivered to the crop is primarily controlled by the travel speed of the gun cart. If the nozzle on the gun cart is pulled rapidly through the field, water application rates can be a low as ¼ inch; if pulled at their slowest travel speed, many models can deliver well over an inch of water. It is important to discuss sprinkler head and nozzle orifice sizes with the system manufacturer when purchasing a gun, as many models come with various options.

Although the sprinkler heads of either system demand high pressure (80 psi or more), the pressure demands of the hose-pull traveling gun systems are greater than those of the cable-pull systems. The hose-pull systems generally use a water turbine or water bellows to pull the hose and gun cart across the field. Since many well-supply pumps and/or irrigation mainlines are unable to support these high pressures for large volumes of water, many models have a booster pump attached at the reel to increase the water pressure to the proper operating range (80 to 120 psi). With a booster pump, the water can travel through the mainlines at a moderate pressure (20 to 40 psi), then be brought up to the operating pressure right as it enters the irrigation unit.

Other Irrigation Systems

Center pivots, wheel line, linear travel and other systems are also available, but these systems are more appropriate for larger fields and are awkward to move from one field to another.

Which System for You?

Choosing the optimal irrigation system for your operation depends on your answers to the following series of questions:

How large an area do you need to irrigate? Hundreds of square feet, thousands of square feet or several acres?

How often will the area need to be watered? Are you taking the edge off of a dry period or will you be watering frequently?

How much time do you have to devote to watering? Moving hoses is time consuming.

What is the size of your budget? Irrigation speed and convenience usually come at a higher price than simple systems.

Also available from UAF Cooperative Extension Service

Trickle Irrigation for Alaska Gardens, FGV-00648.

Managing Irrigation for High-Value Crops, FGV-00649.

Photo of drip tape by David Trainer; photo of center pivot and wheel line system by Jack Dykinga.

To simplify information, trade names of products have been used. No endorsement of named products by the University of Alaska Fairbanks Cooperative Extension Service is intended, nor is criticism implied of similar products that are not mentioned.

Casey Matney, Extension Faculty, Agriculture and Horticulture. Originally written by Jeff Smeenk, former Extension Horticulture Specialist

Reviewed August 2020