Safe Egg Handling for Small Egg-Laying Flocks and Operations

LPM-00344 View this publication in PDF form to print or download.

The information in this publication will assist producers, intermediaries and consumers in ensuring that locally produced eggs are produced and maintained with the highest quality and food safety standards in mind. This publication is a collaborative effort among the University of Alaska Fairbanks Cooperative Extension Service, the Alaska Department of Environmental Conservation and the Alaska Division of Agriculture as part of our effort to promote safe and healthy foods for Alaskans, assist in increasing Alaska’s food security and decrease the amount of foods imported to Alaska. Individuals with fewer than 3,000 laying hens are exempt from mandatory USDA facility registration and inspections, so in the following pages we discuss ways for small producers to promote egg safety from the hen to the final consumer for small producers. Please see appendix A for links to further information.

Layer house management

The condition of the egg that you collect is directly related to how well the flock is managed. Feeding hens a well-balanced ration, supplementing their diet with calcium from oyster shells and providing open water all affect egg quality. In addition, the age and health of the flock can also affect egg quality.

However, since these factors are covered in other publications (see appendix A), this fact sheet will focus on how to determine the quality of eggs and how to properly handle them after they are laid.

Coop and Nest Management

- Keep the laying flock in a secure fenced area separated from wild birds that can transmit disease. Provide them nest boxes so they cannot hide their eggs or nest anywhere they choose. If hens are allowed to nest wherever they choose, you will not know how old eggs are when you find them or what they have been in contact with — if you can find them at all. Eggs laid in nest boxes will also be cleaner.

- Keep birds safe. Don’t attract wildlife to your flock by allowing birds to range free or by leaving feed or waste materials out in the open. Bears, wolves, dogs, foxes and eagles all love domestic poultry. Consider completely enclosing your coop and runs to prevent these predators from preying on your flock. This can be as easy as putting netting over the fenced yard. Once predators discover an easy meal, they will be back causing ongoing problems for you and your birds.

- Provide a clean environment. Keeping the flock’s environment clean and dry will help keep your eggs clean. A muddy outside run, dirty or damp litter and dirty nesting material will result in dirty, stained eggs. Clean out the nest boxes and add deep, clean litter at least every two weeks. Clean out wet litter in the coop and make sure the outside run area has good drainage and is not overgrazed.

- Provide adequate nest space. Supply a minimum of four nesting boxes for flocks of 15 hens or fewer. For larger flocks provide one nest for every four to five hens in the flock. This will help limit egg breakage from normal traffic and daily egg laying. Make sure nests have a deep, clean layer of litter to prevent breakage and help absorb waste or broken egg material. Place nest boxes in dimly lit areas to help reduce or prevent egg pecking.

- Make sure you have perches. Part of the bird’s natural behavior is to roost. Providing flat wooden perches at least 4 inches across will allow the birds a feeling of security and comfort. Perches keep the birds feet warmer and help eliminate health problems like bumble foot.

Collecting the Eggs

A hen’s laying time will vary depending on the temperature of the coop and at what time the hens are exposed to light. It is best to collect the eggs as soon as possible after they are laid, so get to know your flock’s cycle. The longer the egg is allowed to stay in the nest, the more likely it is that the egg will get dirty, broken or lose interior quality.

Collecting eggs at least twice daily is advisable. Collecting three or more times a day may be necessary during winter extremes to prevent freezing. A frozen egg, even if not cracked, can be significantly lower in quality.

Other Considerations for Layer House Management

- Rotate range areas often or allow enough area for birds in outside runs to prevent large dirt and mud areas from forming by overgrazing. Electric poultry fencing or chicken tractors (portable coop and run structures) can be helpful in rotating areas.

- Provide adequate lighting and a heat source during cold weather. Hens need a minimum of 15 hours of light to continue laying through the dark months. It’s best to add light in the morning and not the evening in order to help maintain egg production and to make sure the birds aren’t suddenly caught out in the dark when the lights switch off. Provide enough light so that newsprint can be read anywhere in the coop.

- Provide hens with readily available grit and oyster shells to help strengthen the egg shells.

- Store feed in a metal container and keep feeders up off the ground to discourage rodents.

Proper Egg Cleaning and Handling

- Collect eggs and brush off any debris adhering to the egg shell, then put them in an easy-to-clean container, such as a coated wire basket or plastic egg flat. This will prevent stains from rusted metal and contamination from other materials that are difficult to clean and disinfect.

- Do not stack eggs too high. If collecting in baskets, do not stack eggs more than five layers deep. If using plastic flats, do not stack more than six flats. If you stack eggs too deep you will increase breakage.

- Never cool eggs rapidly before they are cleaned. The eggshell will contract and pull any dirt or bacteria on the surface deep into the pores as the egg cools. Try to keep the temperature relatively constant until they are washed.

- Wash eggs as soon as you collect them. This helps limit contamination and loss of interior quality.

- Wash eggs with water that is at least 90°F. This will make the egg contents swell and push the dirt away from the pores of the egg. If you have extremely dirty eggs, a mild detergent approved by the FDA for washing eggs can be used. Never let eggs soak in water. Soaking eggs in water for as little as one to three minutes can allow bacteria to penetrate the shell and contaminate the egg. The eggs can be sanitized to further reduce the bacteria numbers on the shell by using one tablespoon of unscented household chlorine bleach per gallon of water.

- Cool and dry eggs quickly after washing. Store eggs, large end up, at 45°F and at 75 percent relative humidity. If eggs sit at room temperature (75°F), they can drop as much as one grade per day. If fertile eggs are kept at a temperature above 85°F for more than a few hours, the germinal disc (embryo) can start to develop. If fertile eggs are kept above 85°F over two days, the blood vessels of the embryo may become visible. Eggs stored properly in their own carton or other stable environment will maintain a quality of Grade A for at least four weeks.

Sorting and Grading Eggs

It is best that you sort the eggs before you store, sell or consume them. The easiest way to sort eggs is to candle them with a bright light. This process can help you eliminate cracked eggs or eggs with foreign matter inside, such as blood spots.

Candling eggs: Hold the egg up to the candling light in a slanting position. You will see the air cell, the yolk and the white; the air cell is almost always in the large end of the egg. Put the large end next to the candling light. Hold the egg between your thumb and first two fingers. By turning your wrist quickly, you can cause the inside of the egg to whirl. This will tell you a great deal about the yolk and white. When you are learning to candle, you will find it helpful to break and observe any eggs you are in doubt about.

Note on candling dark brown eggs: In order to properly candle dark brown eggs, you will need a candling light with a magnifier specifically made for eggs. These can be purchased through a poultry supply company.

Identifying cracks: Cracked eggs will appear to have a white line somewhere on the shell. These cracks will open if you apply slight pressure to the shell. Remove cracked eggs and consume them as soon as possible or discard.

USDA grade standard: Use the specifications given in the table below to determine the grade of an egg. Consider shell, air cell depth, yolk outline and albumen quality. GRADING EGGS MAY BE DONE BY THE PRODUCER. One does not need a USDA grader to grade the eggs.

Shell: A normal, high-quality egg has an oval shape with one end larger than the other. The shell should be sound with no cracks, apparent thin spots or ridges that affect the soundness of the shell.

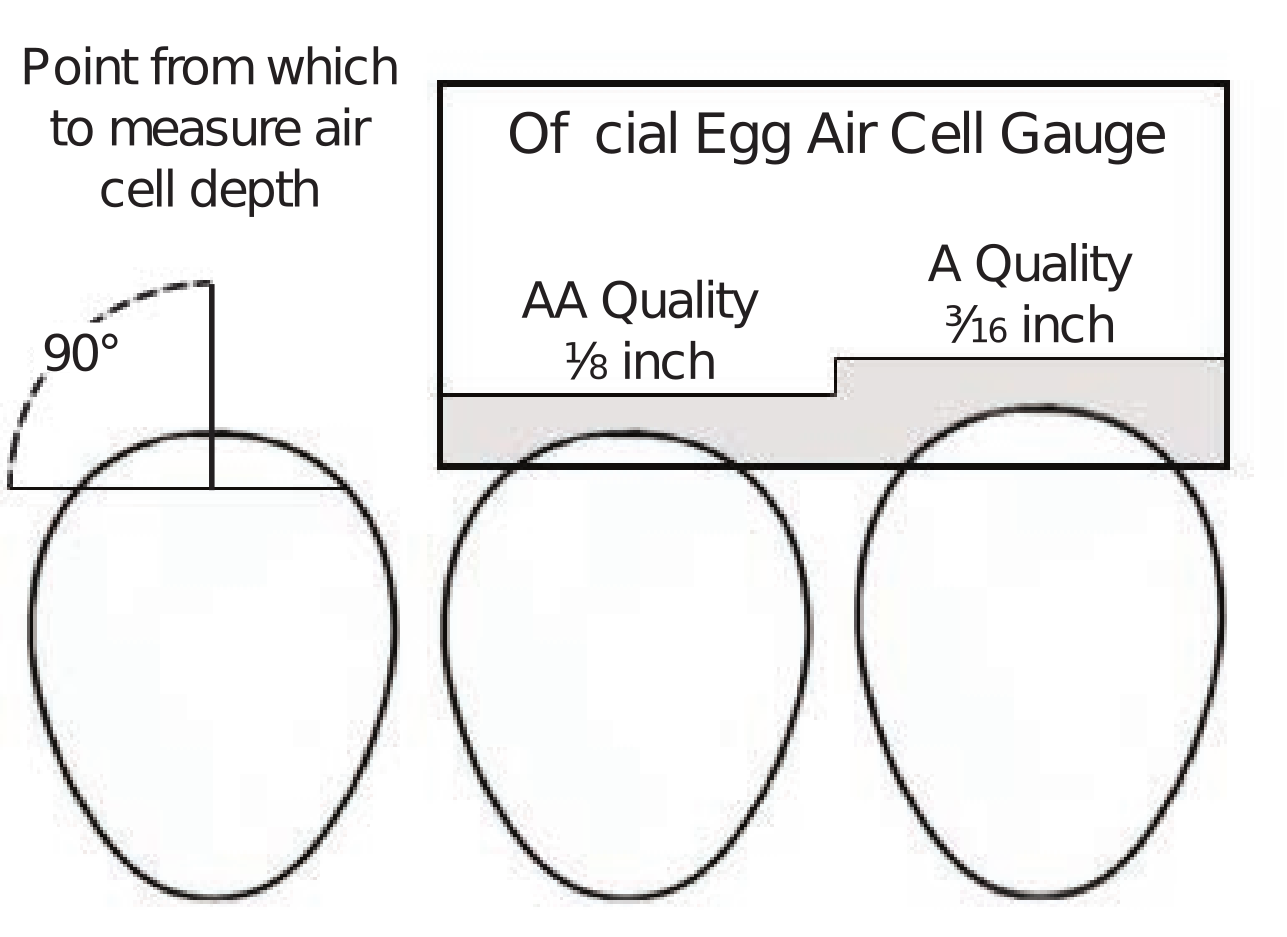

Air cell depth: The depth of the air cell is the distance from its top to its bottom when the egg

is held with the air cell up (see figure 2) In a fresh egg, the air cell is small,

not more than 1/8 inch deep. As the egg ages, evaporation takes place and the air

cell becomes larger, resulting in a lower grade egg.

Air cell depth: The depth of the air cell is the distance from its top to its bottom when the egg

is held with the air cell up (see figure 2) In a fresh egg, the air cell is small,

not more than 1/8 inch deep. As the egg ages, evaporation takes place and the air

cell becomes larger, resulting in a lower grade egg.

White, or albumen: The character or condition of the white, or albumen, can be determined by the behavior of the yolk when the egg is candled. If the yolk retains its position in the center when the egg is twirled, the white is usually firm and thick.

Yolk: The yolk of a fresh, high-quality egg will be surrounded by a rather dense layer of albumen, or white.

| Quality Factor | AA Quality | A Quality | B Quality | Inedible |

|---|---|---|---|---|

| Shell | Clean | Clean | Clean to slightly stained** | Dirty |

| Unbroken; practically normal | Unbroken; practically normal | Unbroken; abnormal | Broken, cracked and/or leaking | |

| Air Cell | ¹⁄8 inch or less in depth | ³⁄16 inch or less in depth | More than ³⁄16 inch in depth | Doesn’t apply |

| White | Clear, firm | Clear, reasonably firm | Weak and watery | |

| Yolk | Outline slightly defined | Outline fairly well defined | Outline clearly visible | Doesn’t apply |

| Spots (blood or meat) | None | None | Blood or meat spots aggregating not more than ¹⁄8 inch in diameter | Blood or meat spots aggregating more than ¹⁄8 inch in diameter |

* For more in-depth grading and egg information, read “USDA Egg Grading Manual” available

at www.ams.usda.gov/AMSv1.0/getfile?dDocName=STELDEV3004502.

** Moderately stained areas permitted (¹/32 of surface if localized, or ¹/16 if scattered.

Therefore, it moves only slightly away from the center of the egg when it is twirled in front of the candling light, and the yolk outline is only slightly defined. As the albumen thins, the yolk tends to move more freely and closer to the shell and the defined outline is more easily seen. A more visible yolk when candled indicates a lower quality egg.

Spots: Eggs with blood or meat spots more than 1/8 inch in diameter are classified as inedible. Eggs with small spots collectively less than 1/8 inch in diameter should be classified as Grade B. The chalaza (whitish, ropelike protein on each side of the yolk that suspends it in the albumen) is distinguished from a meat spot by a bright area of refracted light that accompanies its darker shadow. Blood spot eggs can be consumed without harm; however, people may find the appearance undesirable.

Sizing eggs: It is usually best to size eggs for marketing since consumers prefer medium, large and extra large eggs. Weigh your eggs and use the specifications in the table below to determine size classifications. Egg scales can be purchased through a poultry supply company, but any accurate scale will work.

Egg Sizing Chart

| Size or weight class | Minimum net weight per dozen |

|---|---|

| Jumbo | 30 ounces |

| Extra large | 27 ounces |

| Large | 24 ounces |

| Medium | 21 ounces |

| Small | 18 ounces |

| Peewee | 15 ounces |

Maintaining quality

Refrigeration maintains the quality of the egg. A temperature no greater that 45°F will slow the deterioration of the egg quality and reduce the growth of bacterial pathogens such as salmonella.

The egg is laid at 105°F, the normal body temperature of the hen. As the egg cools, the albumen and yolk shrink away from the shell, forming the air cell. Over time, the albumen loses water and continues to shrink, causing the air cell to increase in size and, thus indicating a decline in quality.

Using the well-known “does-the-egg-float-in-water test” to determine if an egg is edible is not always accurate. If the egg floats, it is old, but it could still be perfectly safe to eat. Instead, crack the egg into a bowl and look for unusual appearance or an “off ” odor. If either characteristic appears or you have any questions or concerns, dispose of the egg.

Over time, the structure of the white and yolk will begin to break down, decreasing the quality of the egg and resulting in an egg with a thinner, more watery albumen, or egg white, and a softer, flatter and weaker egg yolk. If broken open, the egg will spread over a large area with a clear, watery white with reduced leavening and thickening powers; the yolk will be flatter and more easily broken. Using poor quality eggs in cooking or baking may cause a recipe to fail.

Storing eggs

- Store eggs in an egg carton with the small end down to keep the air cell stable.

- Date the carton so you can use or sell the oldest eggs first, and rotate your extra eggs. Try to use or sell all eggs before they are three weeks old.

- Store eggs in a refrigerator with an ambient temperature no greater than 45°F and 70 to 85 percent humidity. Place a thermometer in the refrigerator to track the temperature of your fridge. Never hold eggs at or above room temperature or at low humidity longer than necessary. Leaving eggs in a warm, dry environment will cause quality to drop quickly.

- Never store eggs with materials that have an odor. Eggs will pick up the odors of apples, fish, onions, potatoes and other food or chemicals with distinct odors.

Package (carton) labels

If the eggs are packaged to be sold at a food establishment, they must meet food labeling laws and regulations. To be in compliance, your eggs must be labeled with the following information in English, using at least a ¼-inch font size:

- Statement of identity (eggs)

- Grade and size/weight class

- Numeric count (for example, one dozen, two dozen)

- Name and address of the producer (farm name) distributor, packer or retailer. If the name placed on the label can be found in a telephone directory, only the city, state and ZIP code need to be included. Otherwise, the street address must be included.

- The words “Keep Refrigerated”

| ONE DOZEN |

| GRADE A |

| LARGE EGGS |

| KEEP REFRIGERATED |

| Your Alaska Farm |

| 1234 Alaska Drive |

| Your Town, AK 99700 |

| SAFE HANDLING INSTRUCTIONS: |

| To prevent illness from bacteria: keep eggs refrigerated, cook eggs until yolks are firm and cook foods containing eggs thoroughly. |

Example of label to be secure to top of egg carton.

- Safe handling instructions, with the statement:

- SAFE HANDLING INSTRUCTIONS: To prevent illness from bacteria: keep eggs refrigerated, cook eggs until yolks are firm and cook foods containing eggs thoroughly.

It is acceptable to recycle cartons if the cartons are clean and in good condition and if all labeling information that does not apply is removed. Egg cartons must be free from inspection or labeling marks from previous use.

Specialty Labels

Organic: Eggs cannot be labeled or represented as organic unless the operation has been certified by an accredited National Organic Program certifier. Contact the Alaska Division of Agriculture for more information.

Alaska Grown: Eggs can be sold with the Alaska Grown logo on their label ONLY if they have been Alaska Grown certified.

Transporting and displaying eggs

Eggs should be kept at a temperature below 45°F during transportation to the point of sale. This can be done by keeping the eggs under refrigeration until transport, then using a cooler with gel packs to keep the eggs cool. If the eggs are to be sold at a farmers market or roadside stand, use mechanical refrigeration, such as a small refrigerator or plug-in cooler, if possible. A thermometer should be placed in the cooler so that the temperature can be monitored to ensure that the air temperature in the cooler is below 45°F.

Selling eggs to a food establishment

If the eggs are delivered to or sold to someone who is not the end consumer, such as a food establishment, they must be received at the establishment in refrigerated equipment that maintains an ambient air temperature of 45°F degrees or below. The eggs must be clean and sound and not exceed the restricted egg tolerances for the U.S. consumer Grade B (see egg grading section). The eggs must be properly labeled (see section on package labels).

Regulations for Egg Sales

| No regulations | Alaska Food Code (DEC) Shell Egg Regulations (DNR) |

|---|---|

| From the producer direct to consumer (on-farm sales, farmers markets sales by producer, or roadside stand sales by producer | From the producer to an in mediary* (not final consumer) *Someone other than the producer who sells the eggs at the farmers market, a repacker or retail store |

Resources

Alaska Department of Environmental Conservation, Food Safety and Sanitation Program:

www.dec.alaska.gov/eh/fss/index.htm

Alaska Department of Natural Resources. Division of Agriculture:

Virginia Cooperative Extension Service, Proper Handling of Eggs: From Hen to Consumption:

http://pubs.ext.vt.edu/2902/2902-1091/2902-1091.html

U.S. Department of Agriculture, Animal and Plant Health Inspection Service, “Biosecurity for the Birds” website, accessed April 10, 2011:

www.aphis.usda.gov/animal_health/birdbiosecurity/

The Poultry Site, “Small-Scale Egg Handling — 1,” November, 2009:

www.thepoultrysite.com/articles/1548/smallscale-egg-handling-1

U.S. Department of Agriculture Food Safety and Inspection Service, “Shell Eggs from Farm to Table,” last modified June 9, 2013:

U.S. Department of Agriculture, Agriculture Marketing Service, Agricultural Handbook Number 75, Egg Grading Manual, July 2000:

www.ams.usda.gov/grades-standards/shell-egg-grades-and-standards

This publication was adapted by Stephen Brown, Kate Idzorek, Lorinda Lhotka, Douglas Warner, Amy Pettit and Robert Gerlach from Virginia Cooperative Extension publication 2902-1091, “Proper Handling of Eggs: From Hen to Consumption,” by Phillip J. Clauer. This publication is a collaborative effort between the University of Alaska Fairbanks Cooperative Extension Service, the Alaska Department of Environmental Conservation and the Alaska Division of Agriculture

Stephen Brown, Extension Faculty, Agriculture and Horticulture

Revised August 2020