Suggestions for Installing Domestic Water Storage Tanks

HCM-04950 View this publication in PDF form to print or download.

Introduction

For many Alaskans, sufficient quantities of water may be difficult to obtain from a well, or the home may be out of range of a local utility service. The most common way of dealing with this problem is to install a holding tank and have water commercially delivered. This publication will present general guidelines for installing holding tanks based on state regulations. It should be noted that delivery services, especially truck services, are required to report on the quality of their water and to maintain sanitary delivery methods. This is controlled by the Alaska Department of Environmental Conservation. Each delivery service should have a recent report describing the quality of its water and the results of the most recent test. These tests are repeated regularly to ensure continuing quality of the water delivered.

General Guidelines

Usage rate should be an important consideration when deciding on tank size. Consider how much you are willing to conserve water. In the past, homeowners with little knowledge of water use rates installed 500or 1,000-gallon holding tanks. Although this may seem like an adequate amount of water, most people find it is not enough. A family with this size tank will frequently run out of water and will require deliveries every one or two weeks. Based on standard water use rates and the cost of delivering larger amounts of water, the minimum recommended tank size is 2,000 gallons.

Tank Specifications

Welded steel tanks used to be the most common underground water storage tank in Alaska, but there are unique specifications for water tanks, and the you should talk to the tank fabricator if you are thinking about buying a steel tank. Steel tanks are made in a wide range of sizes and they are competitively priced. However, they are declining in use and their advantages do not outweigh their disadvantages. They are often coated with a epoxy lining to keep them from rusting, but that doesn't always keep them from deteriorating.

Since 2004, the alternative of choice has been the high-density polyethylene (HDPE) tank. These tanks are becoming the standard and are very competitively priced. They have all the advantages of steel and none of the disadvantages. Polyethylene is easy to repair, it doesn't rust or corrode and it is not vulnerable to the normal chemicals that are put into water tanks. For this reason one can expect the tanks to last 100 years. Once it is buried, a polyethylene tank is vulnerable only to chemical or physical destruction. A buried tank it is not exposed to any ultraviolet light, which is the main cause of degradation to plastics. Plumbing failures might also cause it to leak, but generally speaking, polyethylene tanks are the tanks of choice.

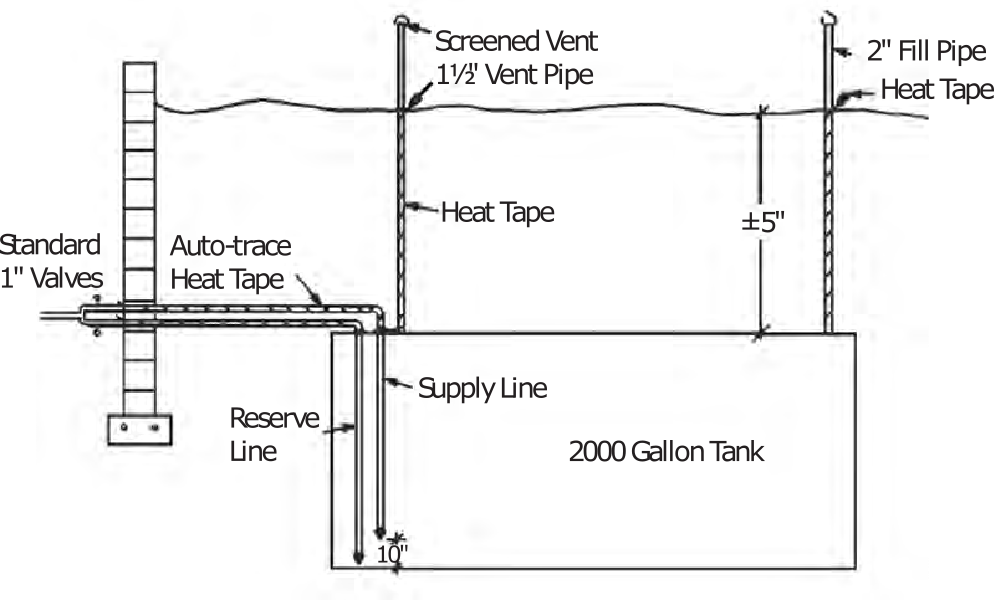

Figure 1 shows a useful feature suggested by Water Wagon, a Fairbanks water delivery company, that serves as a low-level water alarm. The standard pipe delivery port for a double-tap fitting is shown. And then, a second double-tap port is included to provide for a second intake line into the home water system. The down pipe for the standard intake goes to within 10 inches of the bottom of the tank. When the water in the tank drops below this level, the normal supply runs out. The second line provides a reserve tank similar in function to a motorcycle fuel tank. When the water level drops below the intake of the standard line, a valve is closed in that line and another is opened in the reserve line. This allows another 50 to 100 gallons of water to be withdrawn before the water tank is empty.

This serves two useful purposes:

- It serves notice that the water level is low and motivates the homeowner or operator to call for a delivery (presuming they are not on automatic delivery service).

- It allows for a margin of water supply before completely running out.

The second intake fitting must be specified when ordering the tank. It is highly recommended and the additional costs are minimal.

Tank Size

- The average family of four can expect to use 1,500 to 2,000 gallons of water per month. Even that rate requires considerable water conservation.

- 1,000-gallon tanks are simply too small to serve this usage. Owners will find themselves running out of water too often, and delivery companies are hesitant to put small tanks on automatic delivery as the cost escalates with the number of deliveries required.

- Consider a 2,000-gallon tank as a minimum size.

- Bear in mind that the larger the tank, the more efficient the delivery, thus, the cheaper the price per gallon. A large tank can also provide a large reservoir of water for use in case of a fire. Plumbing should be roughed in for this option at the time of installation if you so choose.

- The fill and vent lines should extend at least 2 feet above grade, and preferably 4 feet.

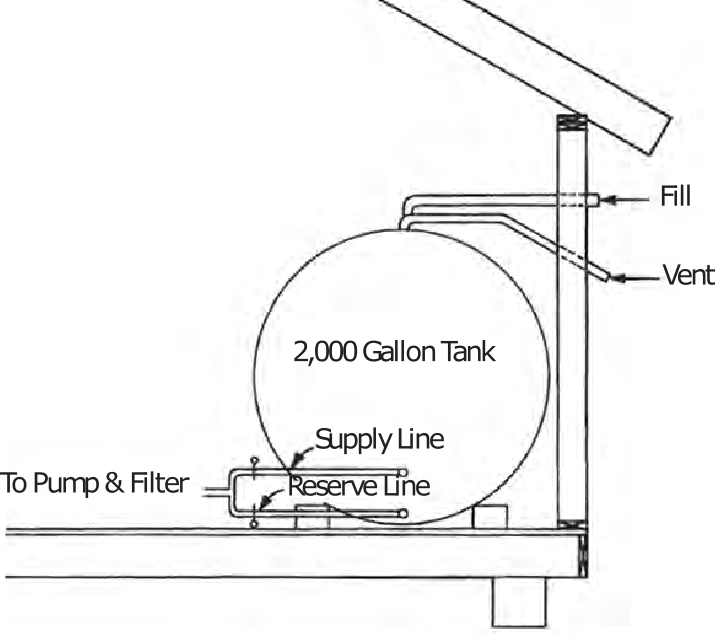

When using tanks for holding water, several measures must be considered for ease of filling and protection from freezing and pollution. You should place the tank in a location where truck access for fill-ups is as simple and direct as possible. Customers should keep their driveway and fill pipe area well maintained in winter. Driveways that aren't plowed are difficult and often create obvious problems. The trucks are wide, long and heavy and do not have 4-wheel drive in most cases. These trucks require a 10-foot-wide clear driving surface and extra room to maneuver around curves, trees and obstacles. The run to the tank from the truck should be 30 feet or less. You should locate the tank as close as possible to a utility room and the distance from the tank to the truck pumping area should be close enough (and clear enough) that the driver can see the tank and vent. Putting the tank in a crawl space is feasible, but the filler and the vent should slope downward and away from the tank to prevent water being trapped in them after filling (see Figure 2).

The vent and the filler should be in plain view and clearly marked with a sign. Filler caps should be blue to indicate that they are water (a red cap indicates an oil filler tank). Keep the water tank as far from fuel tanks as possible. More than once water tanks have been accidentally filled with fuel oil.

Guidelines for Buried Tanks

First, every tank should be flushed with water very thoroughly. Most water storage tanks are buried outside a building. The tank should be a minimum of 4 feet below the surface of the ground. However, this distance can be lessened by insulating the tank from above with 2 inches of Styrofoam rigid board insulation or some other foam insulation. Each inch of this insulation is equivalent to 3.7 feet of soil in insulating value, so it doesn't take much extra foam to protect the tank from freezing. Even so, in extremely low snow years, some ice can form in a tank. Usually this is not a problem. The intent is to protect the tank from freezing in the winter and from mud and possible floating of the tank during breakup or in a heavy precipitation event. The soil should be mounded or graded above the tank to divert surface water. For extra safety, insulate the tank with at least 2 inches of foam insulation, as previously noted.

If an option for thawing frozen fuel lines is desired, electrical, auto-trace heat tape can be installed on the supply line to the structure. The heat tape should not be used continuously but only in the case of an emergency, when it is certain that the supply lines are frozen. If the water line is uninsulated, it should be at least 5 feet below grade, if possible. Uninsulated lines are not recommended.

Burying a tank has several advantages. First, burying the tank avoids using valuable indoor space for water storage. Second, there is no chance of flooding the living space with the water if a leak should occur. And third, if water is stored indoors, 20 to 30 gallons of fuel oil a year can be expended to heat it. Some people feel this is worth the price, but it is not really necessary. Indoor tanks result in cold water not really being cold but closer to room temperature because of inadvertent heating by room air contact.

If soil conditions, such as the presence of rocks or permafrost, do not permit burial of the tank, an insulated shed, preferably attached to the house, should be provided. A full 2,000-gallon water tank however, weighs in excess of 17,000 pounds (81⁄2 tons). Therefore, a reinforced floor is a must. Sealing the system to avoid interior spillage is also very important. This type of installation is detailed in Figure 2.

Avoid burying tanks or water lines under driveways and other cleared areas. Heavy traffic may collapse a tank and the lines. Also, the soil under cleared areas is colder, increasing the likelihood for freezing problems. Before burial, pad the ground beneath the tank with sand to protect the tank from sharp rocks.

Typical Materials List For A Buried Holding Tank 2,000 Gallon Capacity With Reserve Feature

1 — 11⁄2" × 7' galvanized pipe (thread both ends)

1 — 2" × 7' galvanized pipe (thread both ends)

1 — 11⁄2" vent cap with screen

1 — 2" fill cap

1 — 10' heat tape

2 — 2" × 1" double-tap tank adapters

2 — 1" foot valves

1 — 1" × 58" galvanized pipe (thread both ends)

1 — 1" × 48" galvanized pipe (thread both ends)

2 — 1" 90° fittings

2 — 1" copper gate valves (sweat)

1 — 1" copper tee

1" copper pipe (soft) sufficient for need

Auto-trace heat tape with ends

Insulation and polyethylene plastic sheeting

Pump Protection

It is advisable to consider protecting the pump in your water system in case there is a water leak or you run out of water. When you run out of water the pump will attempt to pump water on demand when none is available, and it could destroy itself. To prevent this, there are water level switches and low-pressure pump cutoffs, which can shut the power to the pump off when there is no water in the tank. Many product types are available, and new products are becoming available regularly. Following are a few of these products:

- Mercury float switch, which simply floats when water is present. When contact is made with tank bottom, this switch shuts off the pump.

- Conductive water level-sensing device relies on the conductivity of water to maintain pump operation. When water is absent, the pump shuts off.

Other Types of Tanks

As previously noted, most common tanks are rolled steel tanks or polyethylene plastic tanks. Inevitably, steel tanks are going to be replaced by polyethylene tanks, especially since polyethylene tanks are becoming more durable and stronger so that they can be buried empty. They have none of the disadvantages or shortened lifespan of steel tank.

Aluminum tanks are available in all sizes and applications. They do not rust, are lighter than steel and will last a lifetime (barring damage). However, they cost about twice as much as an equivalent steel tank and have no real advantages over polyethylene. Stainless steel tanks are also available but are about four times as expensive as steel.

Collapsible steel tanks with liners are available. These are especially good for transport to bush locations and other difficult logistical situations. They can be assembled by one man on site and are transportable by small plane or boat.

Further Information

There are many options for on-site water storage not covered in this publication. For further information, call the Cooperative Extension Service in Fairbanks at 474-6366.

Heat Tape

Heat tapes can cause fires if installed improperly. Please read the following consumer product safety commission alert if you are planning to use heat tapes on your water lines.

Buy the proper tape for the proper pipe. Know the diameter and length of the pipe to be protected, then buy the heat tape recommended for that size by the manufacturer.

- Buy heat tape that meets voluntary standards and is listed by a nationally-recognized laboratory such as UL.

- Follow the manufacturer's instructions for installing heat tape. Heat tape should not be lapped over itself around the pipe unless specifically permitted in the manufacturer s instructions.

- Wrap the heat tape directly over the pipe to be protected, never on top of the thermal insulation covering a pipe.

- Don't cover the heat tape with insulating materials unless so advised by the manufacturer. If you insulate the tape, it must be a nonflammable insulating material such as fibrous glass.

- Never use more insulation than recommended by the manufacturer. Over-insulation can cause a fire.

Art Nash, Extension Energy Specialist. Originally written by Richard D. Seifert, former Extension Energy and Building Specialist.

Reviewed March 2023