Summer intern contributes to developing new insulation technology

November 1, 2024

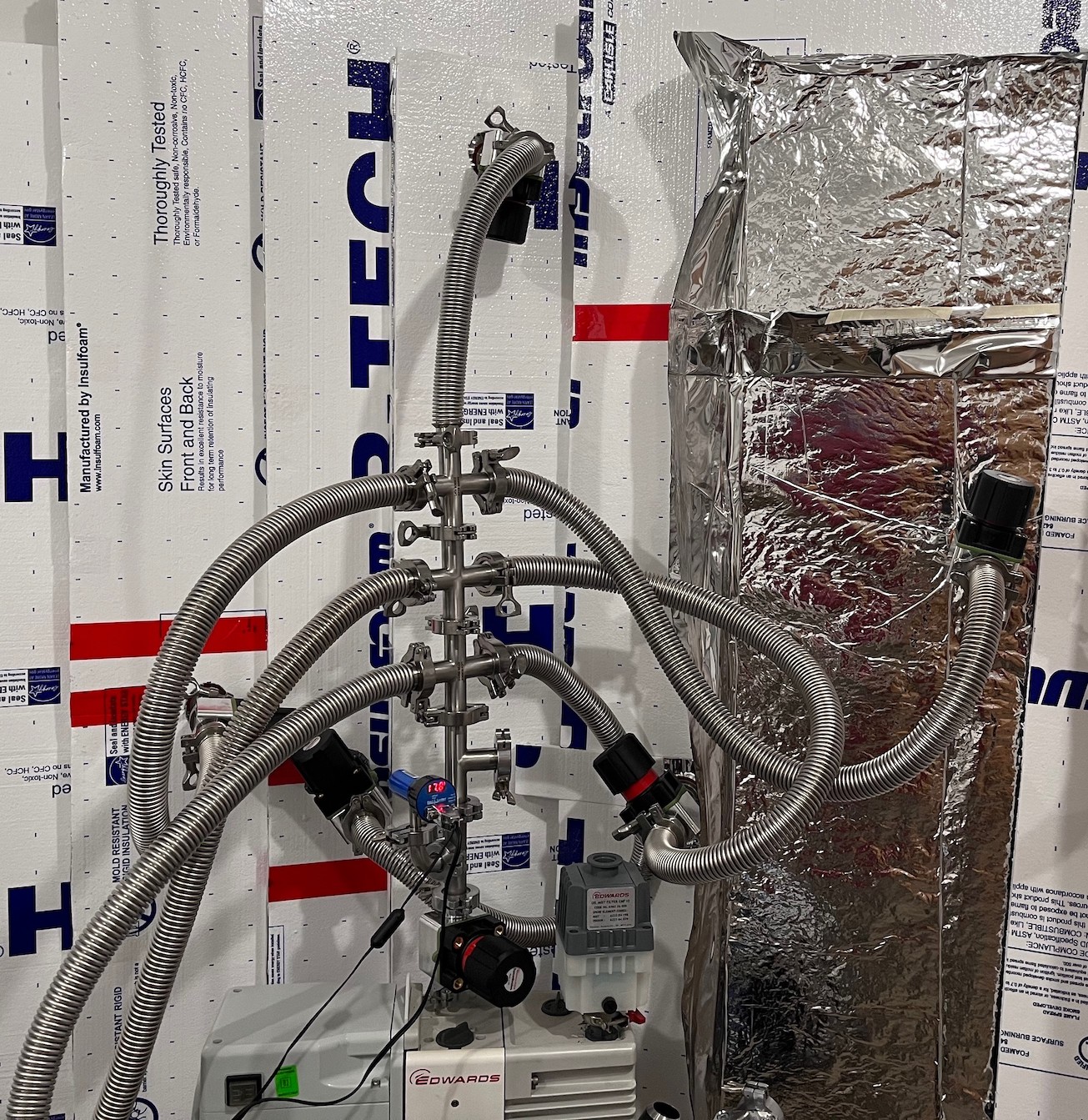

ACEP summer intern Micah VanderHart explains how the vacuum pump is connected to several insulation panels in the active vacuum system during his research presentation.

Homes and commercial buildings, especially in Alaska, require large amounts of energy to heat and/or cool, and because of that are a major contribution to global CO₂ emissions.

ACEP summer intern Micah VanderHart worked under the mentorship of Tom Marsik to develop an insulation system for buildings that is efficient and hence helps reduce CO₂ emissions.

Vacuum insulated panels, or VIPs, are a new type of insulation composed of a sheet of core material such as fiberglass that is vacuum sealed within a large bag. Because a vacuum is the best insulation possible, VIPs can be about 10 times as effective as traditional insulation materials.

While VIPs are currently used in some buildings, they have several drawbacks that hinder wider adoption. They lose their insulation power, for example, because they inevitably leak over time. Any small puncture — during installation or when putting a nail in the wall to hang a picture — instantly ruins their insulation ability.

A prototype of the active vacuum insulation system.

Marsik’s team is developing an active vacuum insulation system to mitigate these issues. It is “active” because a vacuum pump in the building periodically runs to indefinitely maintain the vacuum and preserve the panel’s insulating ability. Additionally, a pressure sensor can detect any punctures and notify the owner so that the leaking panel can be repaired or replaced.

Marsik’s team had built a prototype of this vacuum insulation system. It uses expensive components and is not automated, requiring frequent supervision. VanderHart’s work was to improve the system by sourcing low-cost components and developing a control system to automate the vacuum pump’s operation, thus helping prepare the system for commercialization.

VanderHart used a Raspberry Pi single board computer. It reads pressure from a sensor, and when enough air leaks into the vacuum, it activates the pump to reestablish the vacuum. The Pi will also watch for any issues with the system and ensure everything runs smoothly.

VanderHart said he learned a lot while working on this project. “This was my first major experience coding with Raspberry Pi, working with product vendors and optimizing a complex system for cost.”

This insulation system has the potential to dramatically lower both heating/cooling costs and CO₂ emissions for buildings worldwide. By helping make this system reliable and affordable, VanderHart hopes to bring this technology within the reach of homeowners.

Audience members respond to a question posed by Micah VanderHart during his presentation.

This internship was just the start of VanderHart’s work on this vacuum insulation system, as he decided this will become his master’s degree capstone project. He will continue to develop this project over the next school year, working to physically implement the control system and refine the code.

“I strongly appreciated Dr. Marsik’s mentorship and look forward to continuing to work with him,” he said.

This internship is funded by the Office of Naval Research’s Alaska Regional Collaboration for Technology Innovation and Commercialization program through the ACEP Undergraduate Summer Internship program. View the final presentation for this project on ACEP’s YouTube Channel. For more information on this project, please contact Tom Marsik at tmarsik@alaska.edu.