A Solar Design Manual for Alaska, Sixth Edition

EEM-01255 View this publication in PDF form to print or download.

Art Nash, Extension Energy Specialist, and Chris Pike, Alaska Center for Energy and Power. Originally written by Rich Seifert, former Extension Energy Specialist.

Revised October 2022

Table of Contents

- Acknowledgements

- Foreword

- Introduction

- Photovoltaic Systems

- How Solar PV Works

- Assessing the Solar Resource and Planning the System Layout

- Solar PV Modeling Best Practices

- Publicly Available Solar Resource Datasets

- Basic Solar PV System Components

- Current Standards and Codes

- Net Metering and Interconnection

- Solar PV Economics and Financing

- Grid Connected Solar PV in Rural Alaska

- Off-Grid Solar Systems

- References

- Solar Thermal Systems

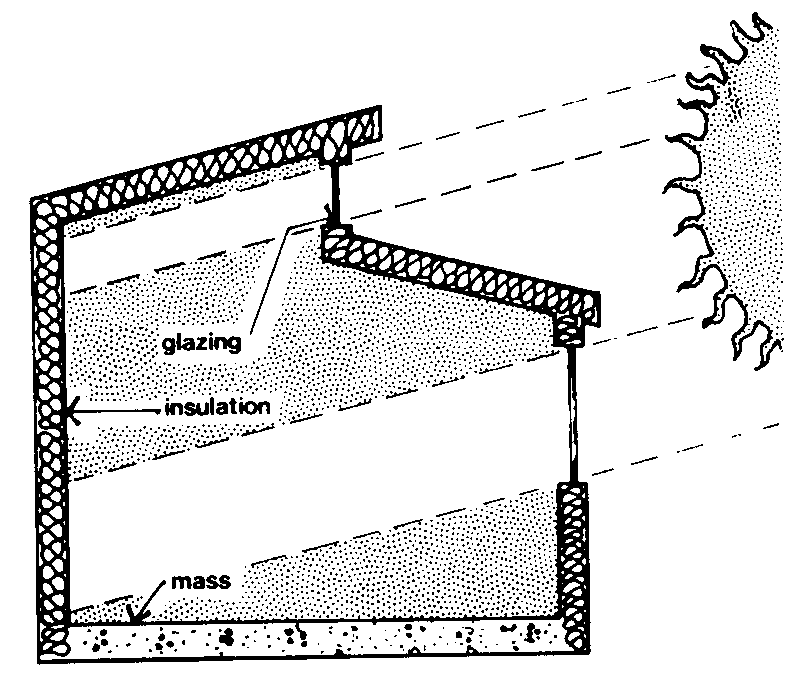

- Appendix A: Passive Solar Heating: An Energy Factsheet

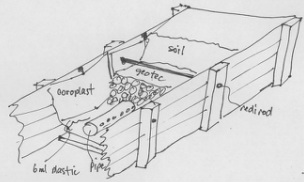

- Appendix B: Solar Greenhouses

- Appendix C: Do-It-Yourself Solar

- Appendix D: F-Charts

- Appendix E: Glossary

Acknowledgements

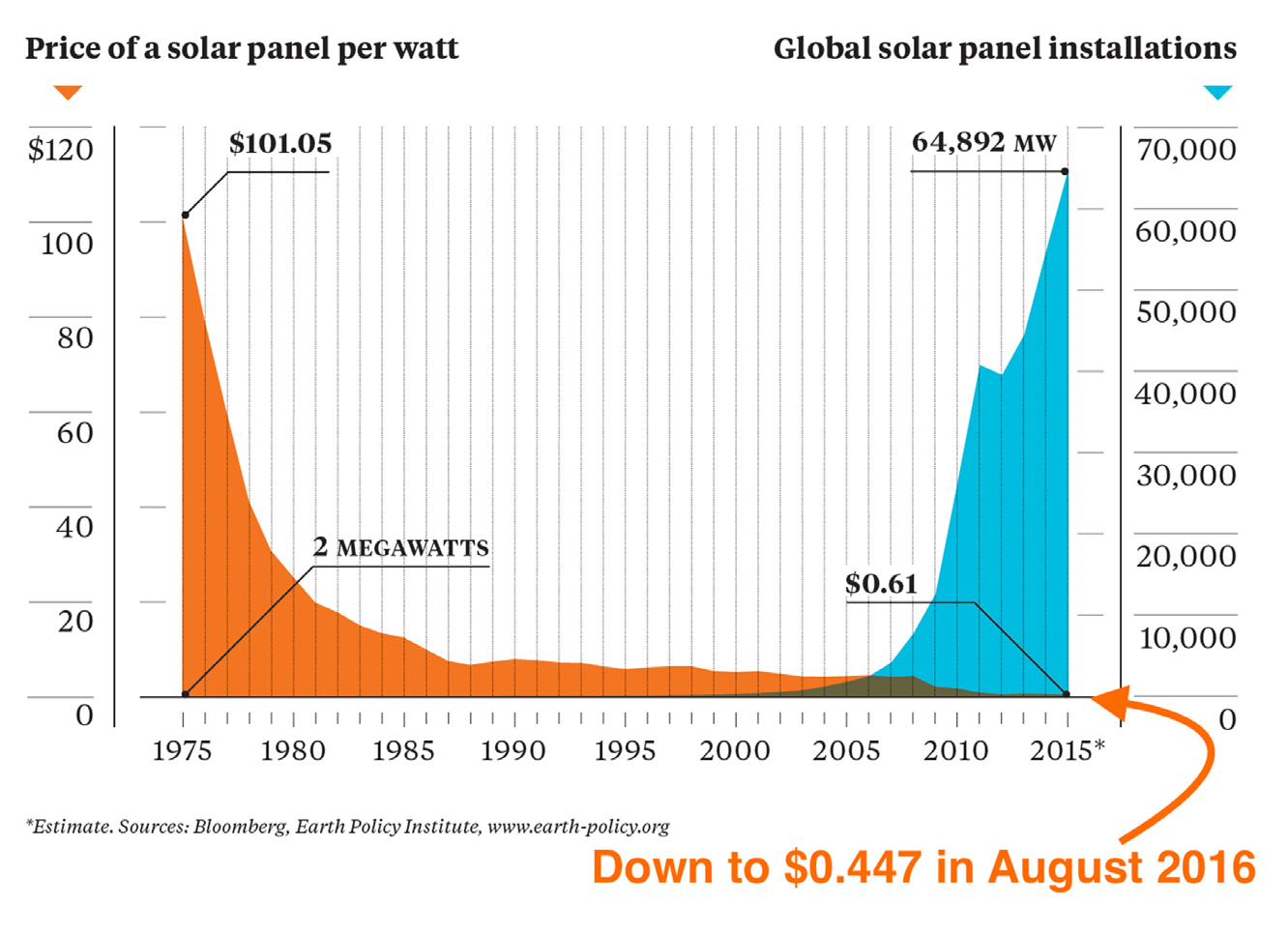

This is the 6th edition of “A Solar Manual for Alaska,” which was first published by Richard Seifert in 1981. In this edition, we’ve significantly expanded the space that is devoted to solar photovoltaics (PV). Solar PV has experienced a dramatic drop in pricing over the past decade, and interest among a variety of stakeholders in the state has grown significantly. We have been fortunate to draw on the experiences of many people throughout Alaska who have installed and lived with PV systems in a variety of situations.

First, I want to acknowledge the UAF Cooperative Extension Outreach and Communications team staff who have been incredibly supportive and helpful during the whole process of rewriting and laying out this edition of “A Solar Manual for Alaska.”

Installers Ben May and Stephen Trimble along with Cady Lister from the Alaska Energy Authority provided the information for the economics and financing section. Jill Fredston and Doug Fester were kind enough to share detailed production data and cost information for their grid-tied roof-top PV system. Julie Estey and Thomas Van Thiel from Matanuska Electric Association, Ben Beste from Alaska Power and Telephone, and Bill Stamm from Alaska Village Electric Cooperative have been kind enough to answer my never-ending questions and contribute the important utility perspectives on distributed solar generation. Art Nash, energy specialist with the UAF Cooperative Extension Service, wrote Appendix A, Passive Solar Heating and Appendix B, Solar Greenhouses. Sam Dennis put together the DIY Solar PV section, which is found in Appendix C. And finally, the following individuals were kind enough to review proposed outlines and give suggestions on ways to improve this publication: Tom Marsik, Cold Climate Housing Research Center; Tony SlatonBarker, Coffman Engineers; Tran Smyth; Dave Pelunis-Messier, Tanana Chiefs Conference; Mark Houston, The Comforts of Home; Mark Haller and Eddie Davidson, Renewable Energy Systems; Ingemar Mathiasson, Northwest Arctic Bureau; Rob Bensin, Bering Straits Development Corporation; Alan Mitchell, Analysis North; and David Nicol, Capstone Solutions; Klaus Dohring and Ian Flood, who delivered a presentation to the Arctic Remote Energy Networks Academy on the Colville Lake solar-diesel system that was used in this manual; Mark Masteller, UAF Bristol Bay Campus; and Erin Whitney, Daisy Huang, and the entire ACEP staff. Personnel support for this manual was funded by Office of Naval Research through the Alaska Hub for Energy Innovation and Development by award number N00014-17-1-2673.

And finally, a special thanks to Rich Seifert, professor emeritus at the University of Alaska Fairbanks for having the foresight to initially publish this manual in 1981 and to push the envelope of solar and building science in Alaska.

— Chris Pike, Research Engineer, ACEP

![]()

Foreword

It’s been eight years since the last edition of “A Solar Manual for Alaska” was published by Rich Seifert and the UAF Cooperative Extension Service. Since that time, Rich has moved to a professor emeritas role, and solar PV technology has changed a lot. It’s an exciting time for solar power in Alaska. Previous attention was on passive solar and solar thermal, which continue to be reliable, established and mature technologies. In the past, however, solar PV was largely relegated to off-grid use because of the challenging economics. Low capacity factors, clunky technology and high prices made grid-tied applications rare in Alaska. Now, however, the price of solar PV continues to drop and in some situations has reached parity with power produced from fossil fuels. Solar PV modules continue to improve, and efficiencies above 20% are becoming common for commercially available panels. Inverter technology has largely become plug and play, and monitoring is becoming standard. All this makes for quicker installs and reduction in labor costs.

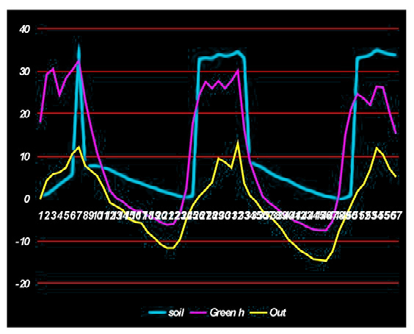

Alaska’s high latitude presents the challenge of having minimal solar energy during long winter months, when energy demand is greatest. At the same time, solar generation in the shoulder months (spring and fall) is often impressive in northern latitudes, where clear skies, cool temperatures, dry air, and bright, reflective snow all support solar generation. Solar PV systems can actually exceed their rated output during these times of year.

On the railbelt, the financial rewards for a solar installation can meet or exceed the rewards a person could expect from other typical investment portfolios. In Alaska, three significant factors continue to impact the growing adoption of solar PV:

- Net metering and grid-tie technology that eliminate the need for storage

- A dramatic 80% drop in solar panel prices since about 2010

- A 30% tax credit subtracted from your federal tax bill

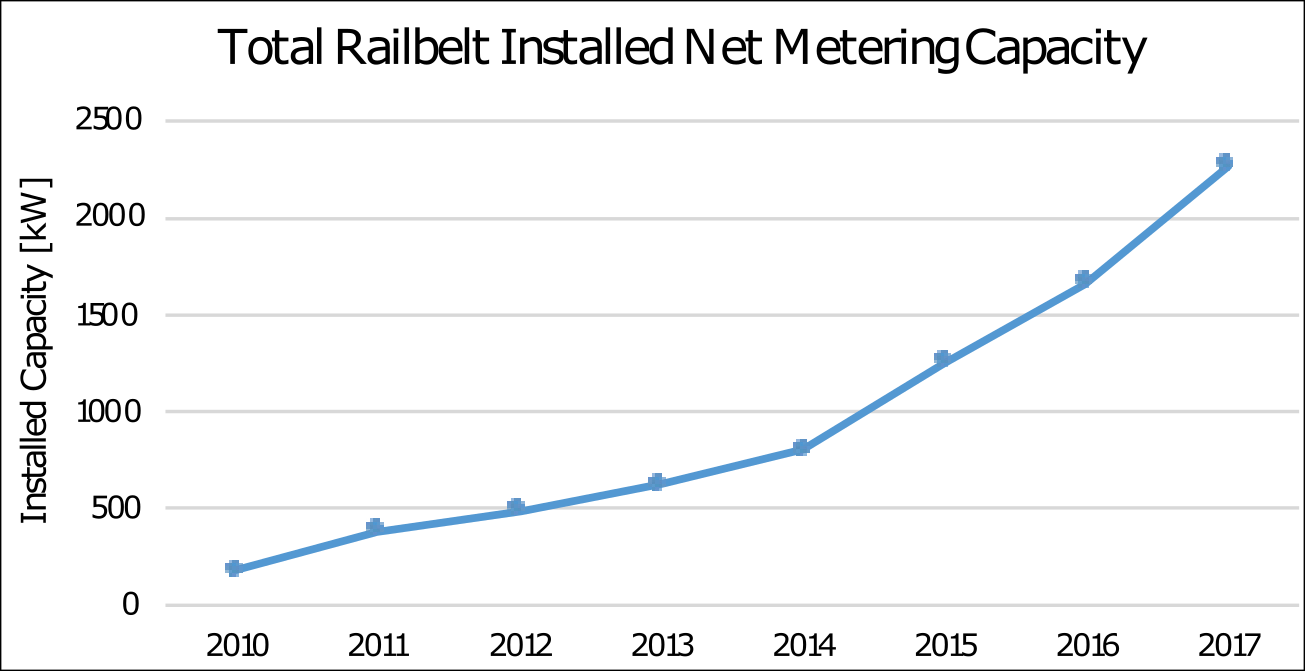

Net metering was instituted in Alaska for qualifying utilities in 2010 and since that time the installed capacity of net metered solar PV has risen from 200 kW to almost 2.5 MW on the railbelt alone. Most of that added capacity has been installed in the last four years. Nationwide, the amount of solar generation capacity for homes, businesses, and organizations grew from 585 MW in 2010 to 4,247 MW in 2016, according to the Solar Energy Industries Association and GTM Research. In Alaska, several hundred kW of solar PV have been installed off the railbelt, although these numbers are harder to track with as much detail. In addition, as of the summer of 2018, there are two different railbelt utilities planning on installing utility-owned PV systems that will be greater than 500 kW each, and in rural Alaska there are many more systems.

The coming years will be even more exciting. Improvements in energy storage technology along with falling prices and improved power electronics and software will allow power to flow in a more decentralized manner. Distributed renewable energy production will continue to play an expanding role in the energy distribution infrastructure.

The last edition of this manual covered passive solar, solar PV, and solar thermal. After consultation with the original author and in an attempt to limit the size and scope of the manual, the passive solar section has been eliminated, although many parts of this section have been integrated into other sections. We continue to stress that the most important thing to do before installing any kind of solar system on your home or business is to search for the ways to improve the energy efficiency of your home. “Efficiency first” is something you will see repeated often throughout this manual — efficiency improvements will nearly always have the quickest economic payback.

This manual is not intended to be a full manual to teach people how to build their own solar system. Still, several people have contributed some of their own experiences building PV systems and these are included in the appendix section. While most parts of this manual are aimed at homeowners and small businesses that are trying to learn more about installing solar, some examples of utility-owned PV are also included.

In the past, solar thermal was the cheaper of the solar options, but this has flip-flopped over the last decade. While solar thermal controls have improved, the actual heat collection technology hasn’t changed at the same pace as its electric-producing counterpart. The original solar thermal section is included in this manual and we encourage people to consider the pros and cons of solar PV versus solar thermal and the appropriate payoffs and decide for themselves which is best for their application.

Solar PV has transitioned from a technology largely associated with off-grid cabins to one associated with investors in suits. Cheaper prices have brought solar into the mainstream, and the associated job growth and investment in the industry have created opportunities for continued economic growth. Alaska is just beginning to experience this.

Introduction

This manual is an attempt to assemble Alaska-specific solar energy design information in a single volume. The manual is organized according to several major subject areas.

The first section is an introductory background discussion of solar energy and some of the important physical concepts necessary to understand it. This is followed by a discussion of Alaska-specific considerations regarding solar energy.

The next major section covers solar photovoltaic (PV) technologies. In the previous addition of this manual it was described as a major emerging option. It is now a robust and mature technology that is widely used in grid-tied and off-grid applications around the world. This section attempts to educate readers about the parts of typical systems, common misperceptions, and important items to remember when considering solar PV for your home or business.

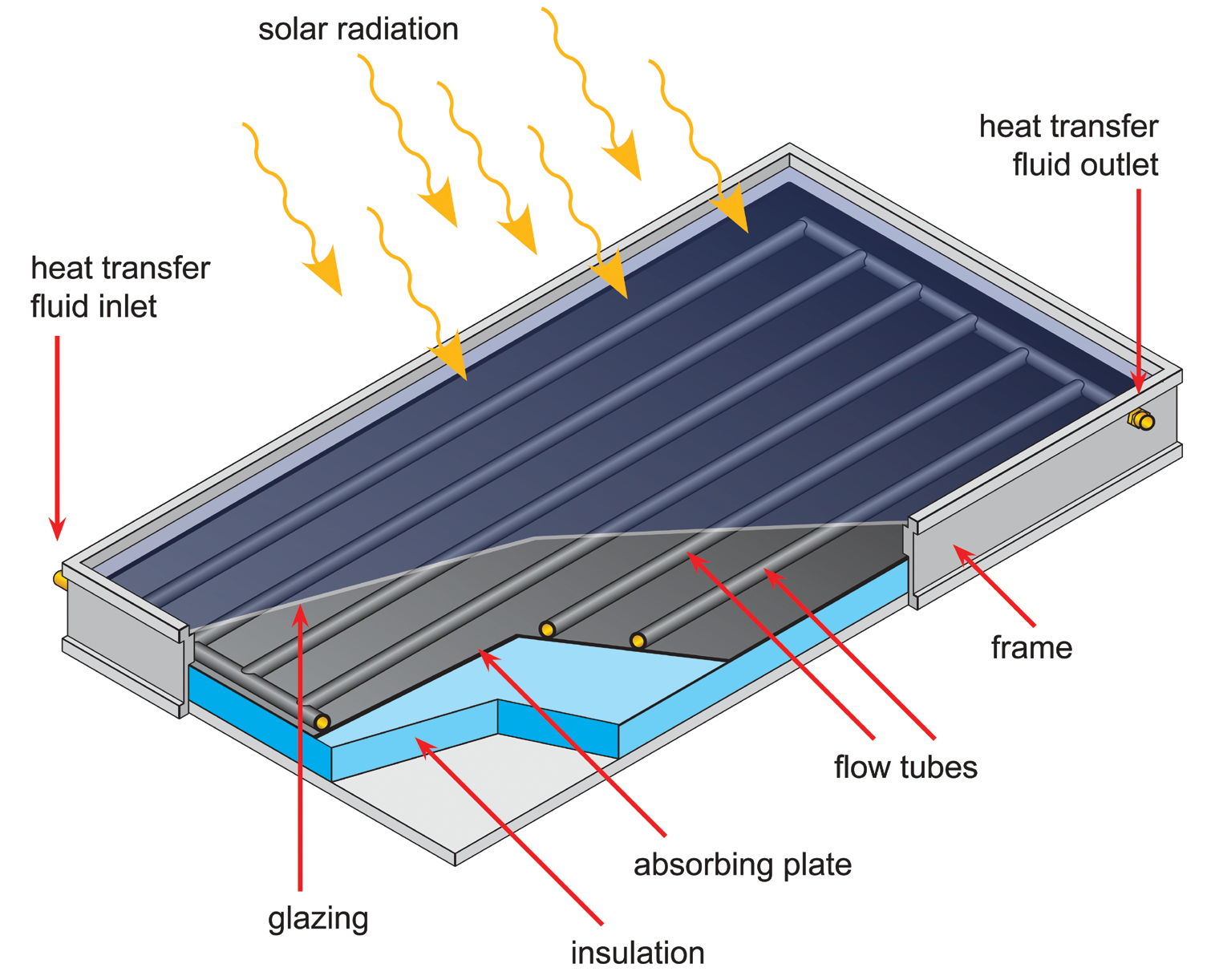

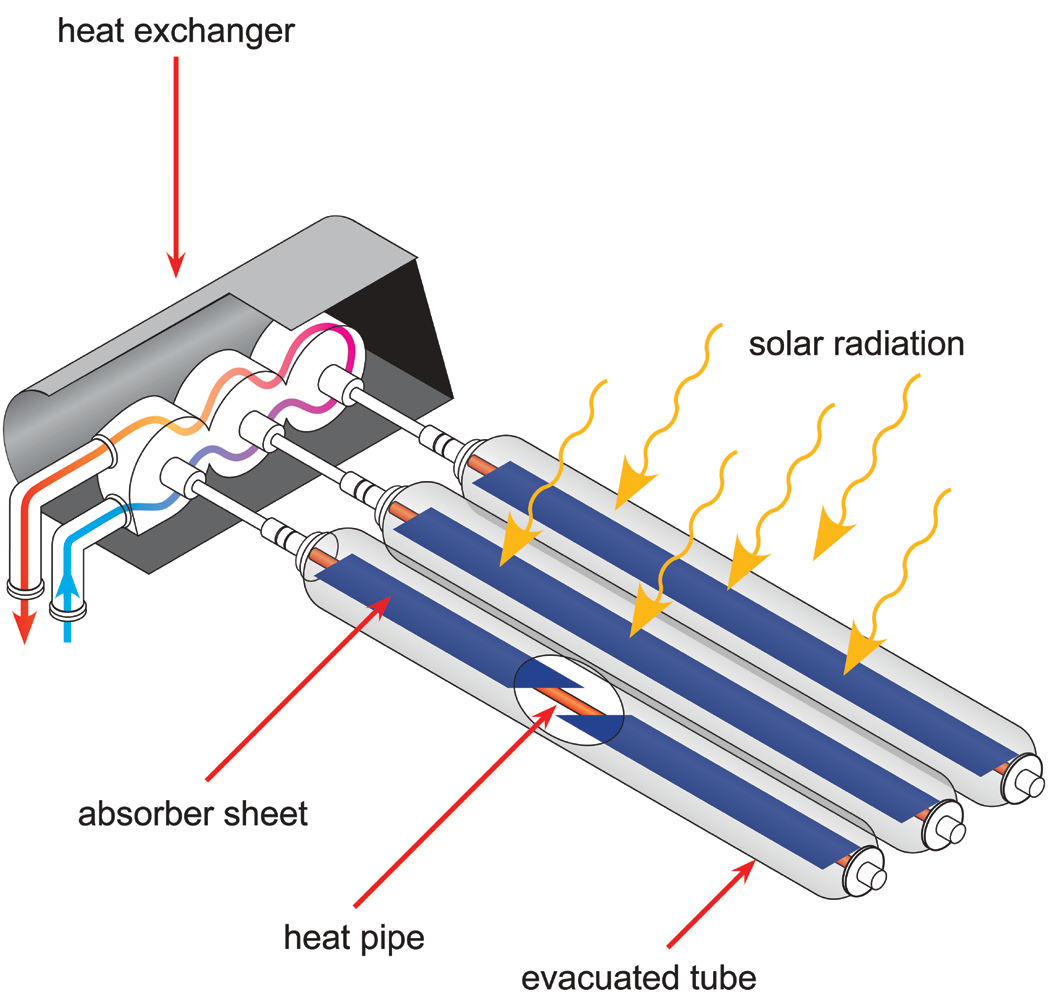

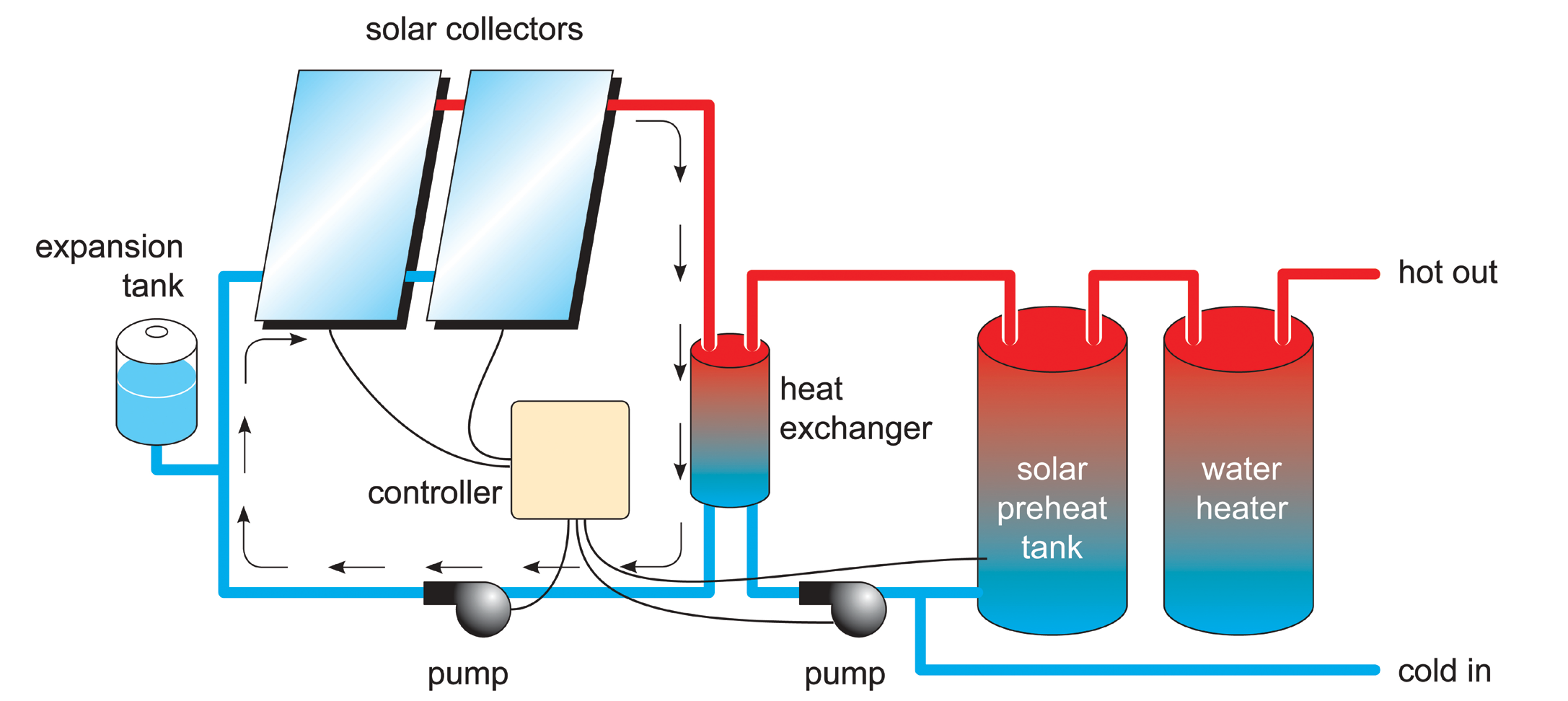

A third section describes the heating of domestic or commercial hot water using solar energy. This section discusses factors such as the solar geometry at high latitudes, shading, and snow cover effects, all of which influence the performance of solar hot water heating systems. Solar thermal technology has not undergone as many changes since the last edition as solar PV, and much of this section remains unchanged.

A Short Course in Solar Energy

The sun is a virtually limitless source of energy. It has been burning for about 5 billion years and will burn for approximately 5 billion more — virtually forever on the human scale. Solar energy is radiation. Most early solar technologies captured this radiation as heat, but as the use of solar photovoltaics has become more widespread, technologies that convert solar energy directly to electrical energy are now commonplace.

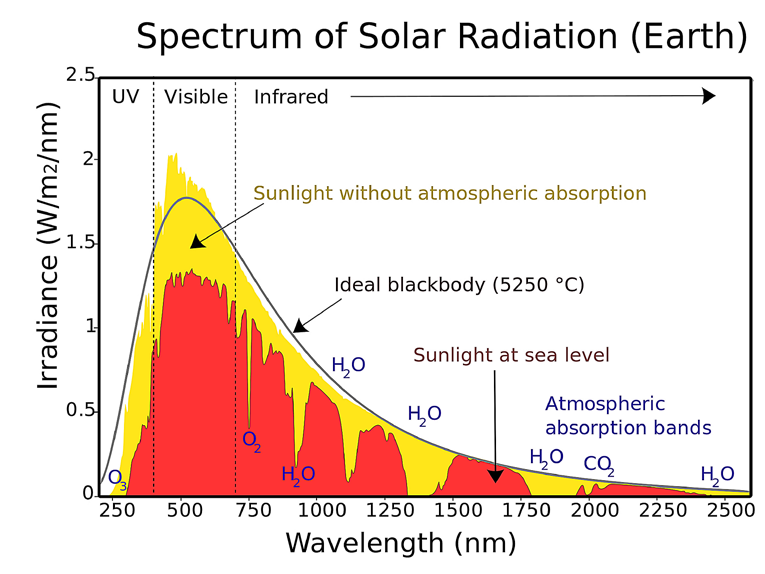

The solar radiation spectrum is composed of UV infrared radiation, visible light, and ultraviolet light. Visible light is the largest component of solar radiation. Wavelengths shorter than visible light (called ultraviolet) are largely absorbed in the upper atmosphere. The other major component of solar radiation, infrared, has longer wavelengths than visible light. We perceive infrared radiation as heat. A hot object emits infrared radiation, allowing us to sense the object without touching it. Over 90% of the solar radiation reaching the Earth’s atmosphere is visible light and near-infrared radiation, while ultraviolet (UV) light makes up less than 10% of solar radiation. Figure 1 illustrates the solar spectrum.

The amount of available solar radiation is not constant. Solar altitude, the height of the sun above the horizon at midday, and day length vary with the season. Light intensity changes with the time of day. Environmental conditions further modify the amount of solar energy that the surface of the earth receives at a particular location or time. Yet the sun does emit a relatively constant amount of radiation with time. Referred to as the solar constant, the amount of solar radiation at the outside of the atmosphere facing the sun is about 1,350 watts/m2, equivalent to 428 Btu/ft2/hr. A Btu (British thermal unit) is the amount of heat needed to raise the temperature of a pound of water by 1°F.

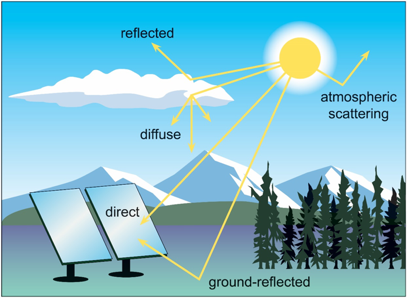

As solar radiation passes through the atmosphere, some continues in a straight path and some is scattered by the atmosphere. The former is called beam, or direct, radiation and the latter is called diffuse radiation. Beam radiation enables shadows to be cast, and diffuse radiation is characteristic of overcast days. Diffuse radiation comes from all directions in the sky, so it cannot be focused. It is still useful to those solar systems that don’t require focusing of the solar radiation. A third type of radiation that is important in Alaska is often referred to as reflected radiation, radiation that is reflected off the ground before it reaches the aperture plane of the collector (Horta et al., 2008). Solar radiation received on a surface is usually a combination of all three of these components (Figure 2).

Irradiance

Irradiance is the term used to describe the total amount of solar radiation energy received on the surface, measured in Watts/meter2 (W/ m2 ). Depending on many factors, including weather and atmospheric scattering, different locations receive different proportions of direct and diffuse radiation. Typically, dry desert conditions receive the highest proportion of direct radiation. Insolation describes irradiance over time. For example, if a location is receiving 1,000 W/m2 for one hour, then the insolation received is 1 kWh/m2.

Peak Sun Hours

Many solar professionals describe the solar resource in a particular area as the number of peak sun hours (or simply sun hours) that a region experiences. 1,000 W/m2 is generally accepted as the maximum irradiance level that is achieved at the surface of the Earth. In reality, irradiance levels can be higher in certain clear, dry conditions and at high elevations. In Alaska, there are time periods in the spring when clear, cold conditions occur along with highly reflective white snow cover snow, which allows irradiance levels to exceed 1,000 W/m2. Peak sun hours refers to the solar energy which a particular location would receive if the sun were shining at its maximum value for a certain number of hours. To calculate peak sun hours divide 1,000 W/m2 into the total insolation for a day. If total insolation for the day was 5,000 Wh/m2, then one could say that there were five sun hours on that day. Understanding this terminology and the concept of peak sun hours can be helpful when learning about solar energy. Some irradiance maps also express the irradiance by the average daily sun hours on an annual and monthly basis. We will use this terminology throughout this guide.

Solar Energy in Alaska

The potential for using solar energy in Alaska has long suffered from the notion that the sun simply doesn’t offer any hope for Alaskans. Alaska is not Arizona, and it is true that from roughly November 15 until the end of January, little solar radiation is available, and optimizing a system to collect it is not economically feasible. So, what can the sun provide?

Despite long, dark winters, northern latitudes actually receive some bonus daylight because of the long sunrises and sunsets. There are 230 hours more of possible sunlight at the Arctic Circle than at the equator (Hartman et al., 1978), but there are other factors responsible for the amount of available solar energy besides visible light. The challenge with solar energy in Alaska is that it is dynamic, not reliable, and out of phase with the space heating loads in the state. Yet these challenges can be overcome. Solar energy is on-site, and not subject to transportation system failures. It creates few environmental problems. Solar energy is not inflationary, and it is spread relatively evenly across the planet. The price to harvest solar energy has fallen dramatically over the last decade, and solar PV has no moving parts and minimal ongoing maintenance costs.

Availability of Solar Radiation

The northern latitudes and the Alaska climate are the two most significant factors affecting solar radiation in the state. Both will be discussed below.

Latitude

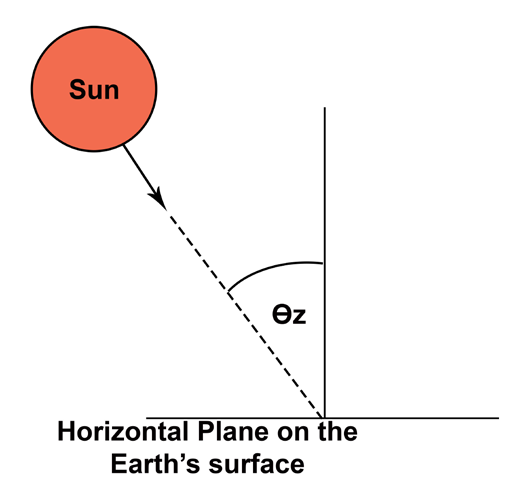

As a very general rule, the farther from the equator a location is, the less solar energy it receives on an annual basis because the intensity of solar radiation is proportional to the angle of the sun above the horizon (solar elevation). As any Alaska resident can attest, the solar resource in Alaska is subject to the annual variability related to latitude. Not only does day length change from approximately 3.5 to 4.5 hours in winter to 20 to 22 hours in summer, depending on the location, but the elevation angle varies in Fairbanks from a meager 2.6° above the horizon on December 21 to 49.5° above the horizon on June 21. The sun is never overhead (at 90°) in Alaska. The maximum height it can reach above the horizon for any place north of the tropics can be calculated by subtracting the latitude from 113.5°. Thus at 64°N the highest solar elevation that the sun reaches is 113.5° – 64° = 49.5°. The actual length of the path that the sun’s rays travel through the atmosphere divided by the minimum possible path of travel if the sun were directly overhead is called the air mass ratio, and it is a useful tool for demonstrating why even on clear days, the maximum available solar radiation is limited in the far north in the middle of winter. The air mass ratio is equal to 1/cos θz, where θz = the zenith angle. The zenith angle is the angle between the zenith and the center of the sun as shown in Figure 3.

The air mass ratio shows that the more atmosphere solar radiation travels through, the more it is reduced. For example, Table 1 shows the theoretical maximum irradiance in Anchorage and Fairbanks during the winter and summer solstices and the spring equinox. This calculation does not take temperature, humidity, albedo, weather, or other similar climactic factors discussed earlier into account, but it helps demonstrate the potential irradiance at various time in the year on a perfectly clear day. In the middle of winter, when the sun is very close to the horizon, there is just not a lot of solar irradiance available in the far north. But starting in February strong solar irradiance begins to return to Alaska.

| December 21 | March 20 | June 21 | |

|---|---|---|---|

| Anchorage | 280 W/m2 | 841 W/m2 | 980 W/m2 |

| Fairbanks | 100 W/m2 | 790 W/m2 | 970 W/m2 |

Table 1. The theoretical maximum irradiance based on the air mass ratios is shown for Anchorage and Fairbanks. This does not take temperature, humidity, albedo, weather, or other similar climactic factors into account.

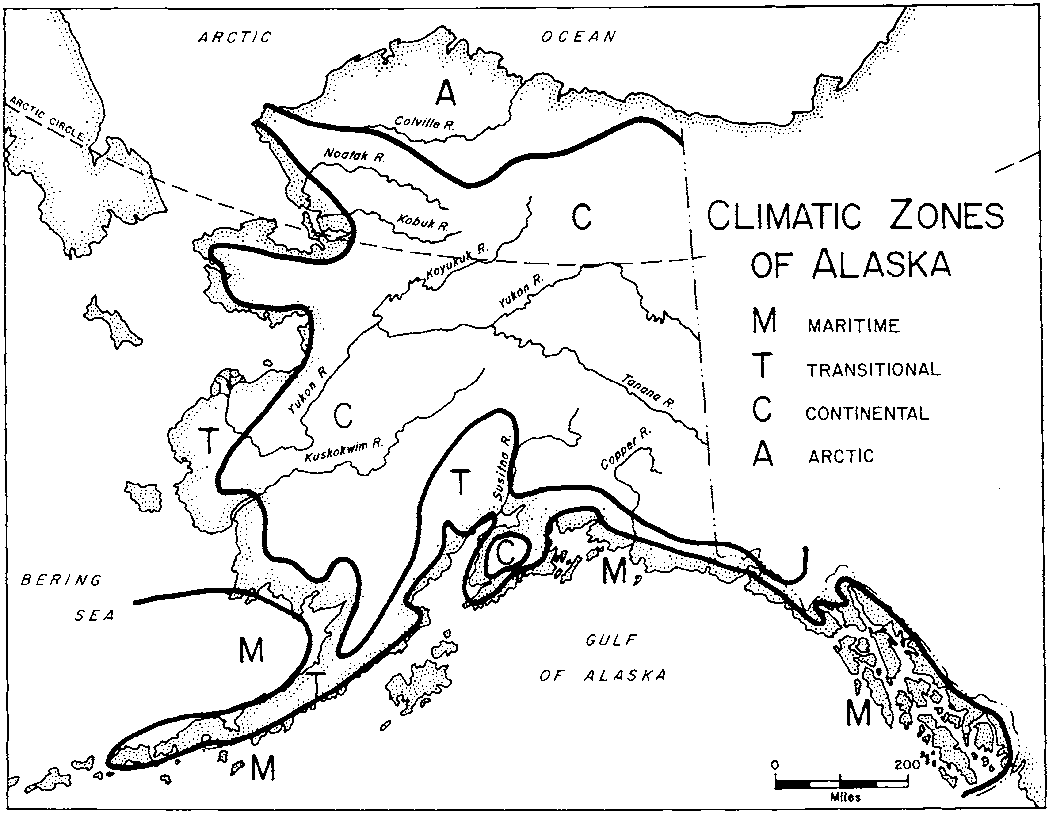

Climate

Sometimes solar radiation does not always correlate well with latitude. While latitude is one factor that determines irradiance, the local climatic effects of oceans, mountains, and other geographical elements in Alaska play a more dominant role. Rain shadows caused by large Alaska mountain ranges such as the Chugach and Alaska ranges isolate the Interior and continental climatic regions of Alaska from cloudy weather and precipitation. For these reasons, practical applications of solar energy are most feasible in the continental and transitional areas of Alaska. Both of these areas dominate the Alaska Railbelt (see Figure 4). The definitions of these areas are given below:

Transitional: Pronounced temperature variations throughout the day and year. Low precipitation and humidity. Surface winds generally light. Mean annual temperature generally 25° to 35°F.

Continental: Dominated by continental climatic conditions. Great diurnal and annual temperature variations, low precipitation, low cloudiness, and low humidity. Surface winds generally light. Mean annual temperature 15° to 25°F.

One important factor that directly relates to the state’s climate is what people involved in the solar industry often refer to as “the spring bump.” It is characterized by high power outputs from solar PV panels and is a result of three factors:

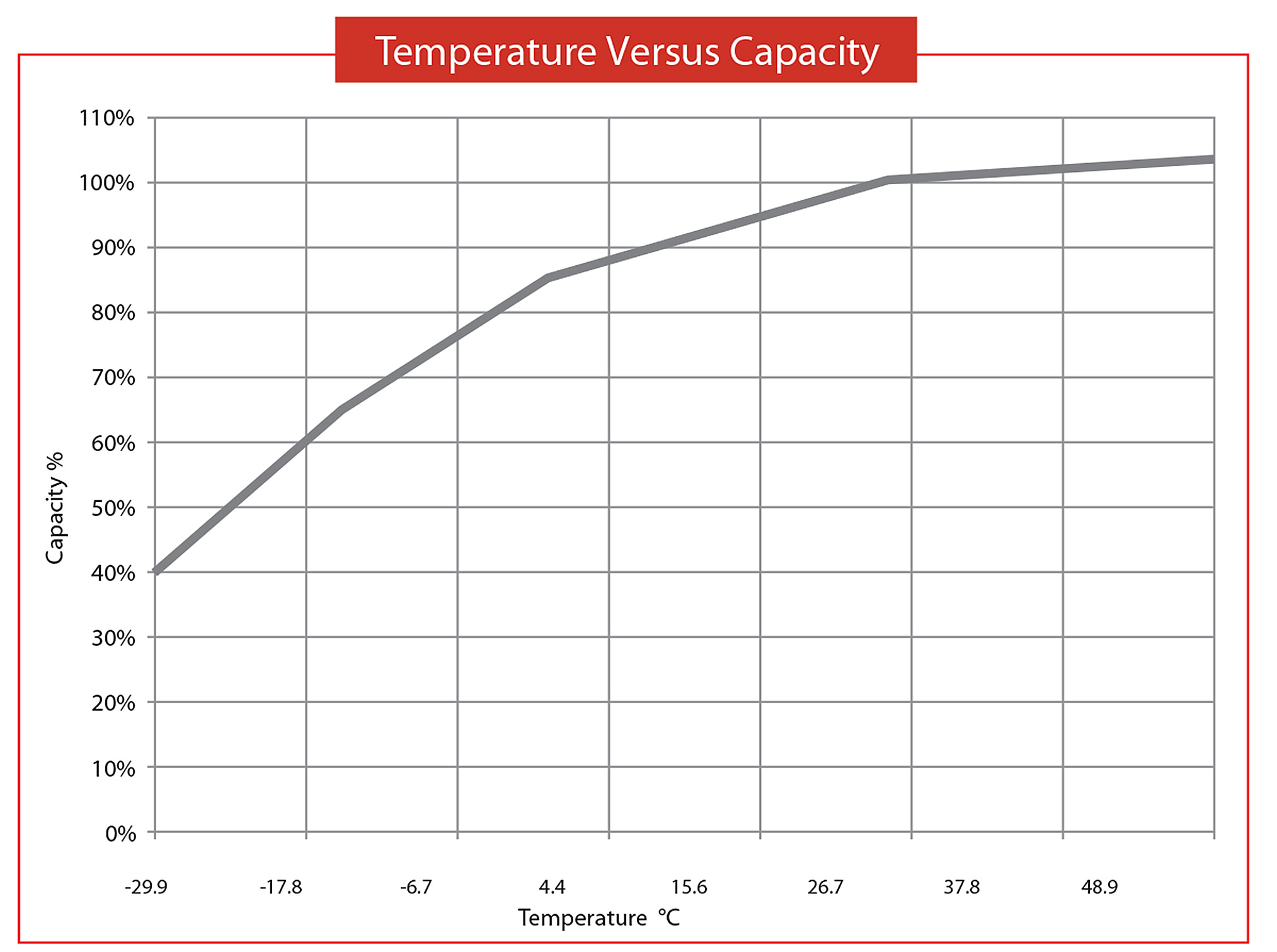

- Solar PV panels operate more efficiently during cold springtime temperatures.

- Bright sunny days start returning in mid-February.

- Bright, white snow cover has a high albedo and reflects lots of light off the ground and significantly adds to the solar radiation received by steeply angled solar panels.

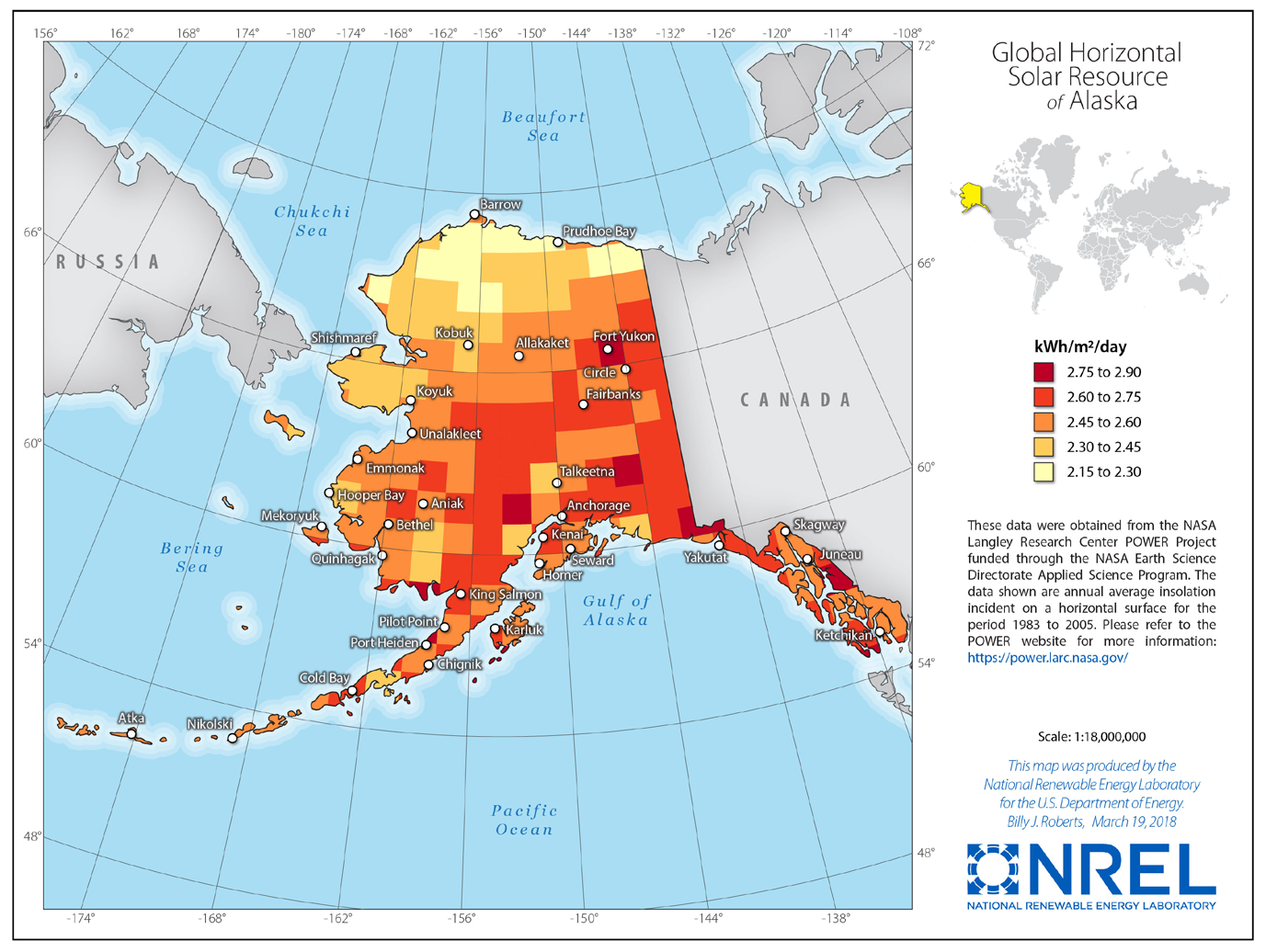

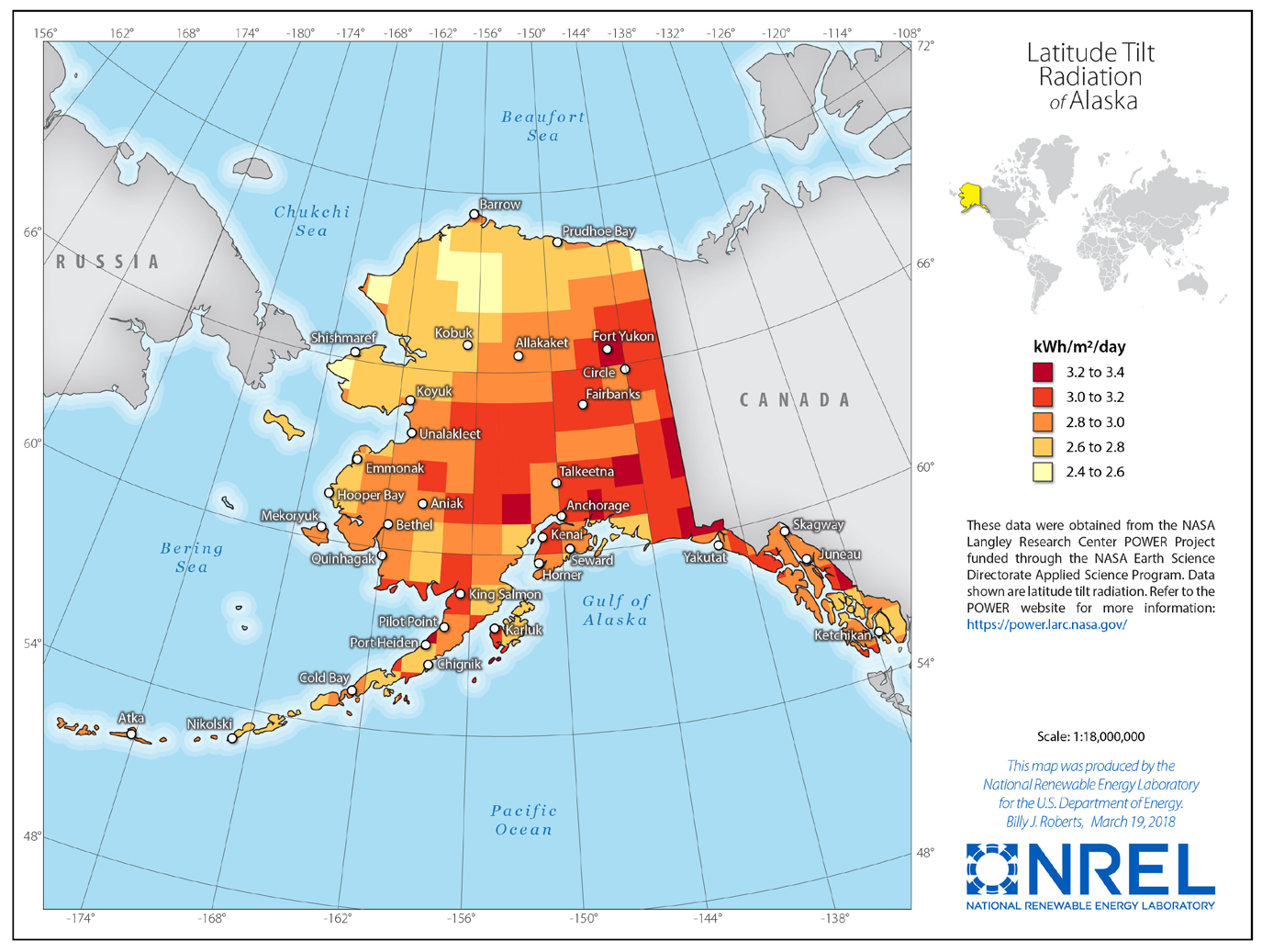

Figures 5 and 6 on pages 10 and 11 show solar irradiance maps produced by the National Renewable Energy Lab (NREL).

Common Applications of Solar Energy

The most common applications for solar energy are the generation of heat and electricity. Both will be covered in varying degrees in this manual

Photovoltaics (solar electricity)

Solar energy can be directly converted to electricity using photovoltaic cells. This application was once used almost solely for power in remote locations. Recently, however, it has become common in grid-tied applications at the residential, community, and utility scales. Photovoltaics in Alaska have made great advances in the past 30 years. The growth in the state solar industry can be seen in Figure 7, which shows Railbelt net metering growth since 2010, most of which is the result of solar PV installations. Systems larger than 25 kW do not qualify for net metering and are not included in this figure.

This manual includes a detailed discussion of photovoltaic solar applications, but it should not be considered an installation manual. Photovoltaics technology is constantly changing and often requires professional assistance to properly install and maintain.

Solar Heating

Solar thermal technology is the heating of a fluid using the sun’s energy. Typically this is done using an auxiliary energy source to move heat from where it is collected to where it is used or stored (usually by a pump or fan). Active solar technologies are practical for providing domestic hot water in Alaska.

Spurred by renewed interest in producing more of the food consumed in Alaska locally, there is a growing interest in greenhouse and agricultural use of solar energy. See Appendix B for solar options available to growers.

References

Hartman, C. W., and Johnson, P. R. (1978). “Environmental Atlas of Alaska.” University of Alaska Fairbanks, Institute of Water Resources.

Horta, P., Carvalho, M. J., and Fischer, S. (2008, October). Solar thermal collector yield: experimental validation of calculations based on steady-state and quasi-dynamic test methodologies. In “Eurosun 2008: 1st International Conference on Solar Heating, Cooling and Buildings.”

Photovoltaic Systems

How Solar PV Works

Solar photovoltaic cells convert solar energy to electrical energy. Together a group of PV cells make a module. Solar cells are small, square-shaped semiconductors made from silicon and other conductive materials. When packets of solar energy called photons interact with solar cells, electrons are displaced and form the DC electricity that flows out of the PV modules towards the load. Depending on the type of PV installation, the electricity flows through a series of storage and power electronics devices before it is delivered as 110 V AC electricity to the appliances in your home.

In the early days of residential PV, all systems were installed in homes that were not connected to the utility electrical grid. These systems required storage to provide energy when the sun was not shining. Power electronics were primitive by today’s standards and inverters were not as efficient or reliable as they are today. Because of this, many of these early off-grid solar homes used DC electrical appliances so that they could use power straight from the panels and batteries. DC appliances tend to be more expensive and harder to find than their AC counterparts, and recently most homes that use solar power, whether on-grid or off-grid, use inverters to convert the electricity to AC. In those early days, the cost of solar could never compete with the price of electricity supplied by the grid. People who self-generated did so either out of necessity or for ideological reasons. This is no longer the case in many locations. Advances in technology and reductions in component pricing have made solar price-competitive with most forms of electrical generation. System economics will be discussed later in this guide.

The purpose of this chapter is to give the reader an understanding of how a basic solar PV system works so that readers can understand how the components work together and what design considerations they need to be aware of. It is not the purpose of this chapter to teach you how to become an electrician or a PV design pro. Electrical wiring is serious business. Most solar electric systems produce lethal voltages, and even those that don’t can burn a house down if wired improperly. If you are unsure of what you’re doing please err on the side of safety and consult a licensed electrician or other qualified professional before purchasing materials or starting to work on any electrical project.

10 Key things to remember if you are thinking about installing a solar PV system

- Energy efficiency is the most important part of a well-planned system. Assess your building for energy saving potential as part of your solar planning.

- Communicate with your utility early in the planning process and make sure you understand their rules and regulations regarding distributed generation.

- Choose a credible PV manufacturer; do NOT be willing to be the first field test.

- Choose a credible installer who has experience installing systems in your area.

- Read the utility interconnect agreement carefully. Many utilities have minimum liability insurance requirements.

- Familiarize yourself with the available tax credits and consult with a tax professional if necessary

- Take time to investigate the different financing options which may be available to you.

- Does your roof have less than ten years of life left? If so, it might be wise to reroof before installing a rooftop PV system.

- Make sure your electrical service is up to code. If it’s not, you will likely have to bring it up to code before installing solar PV.

- What are the goals for your solar PV system? Will the modeled solar energy production align with these goals?

Assessing the Solar Resource and Planning the System Layout

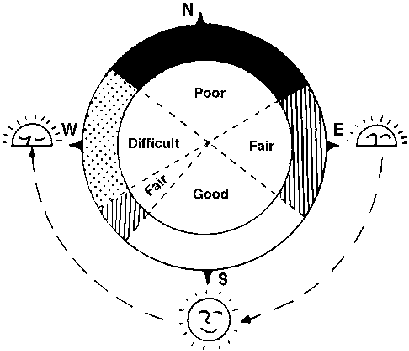

Geometry of Solar Collection in Alaska

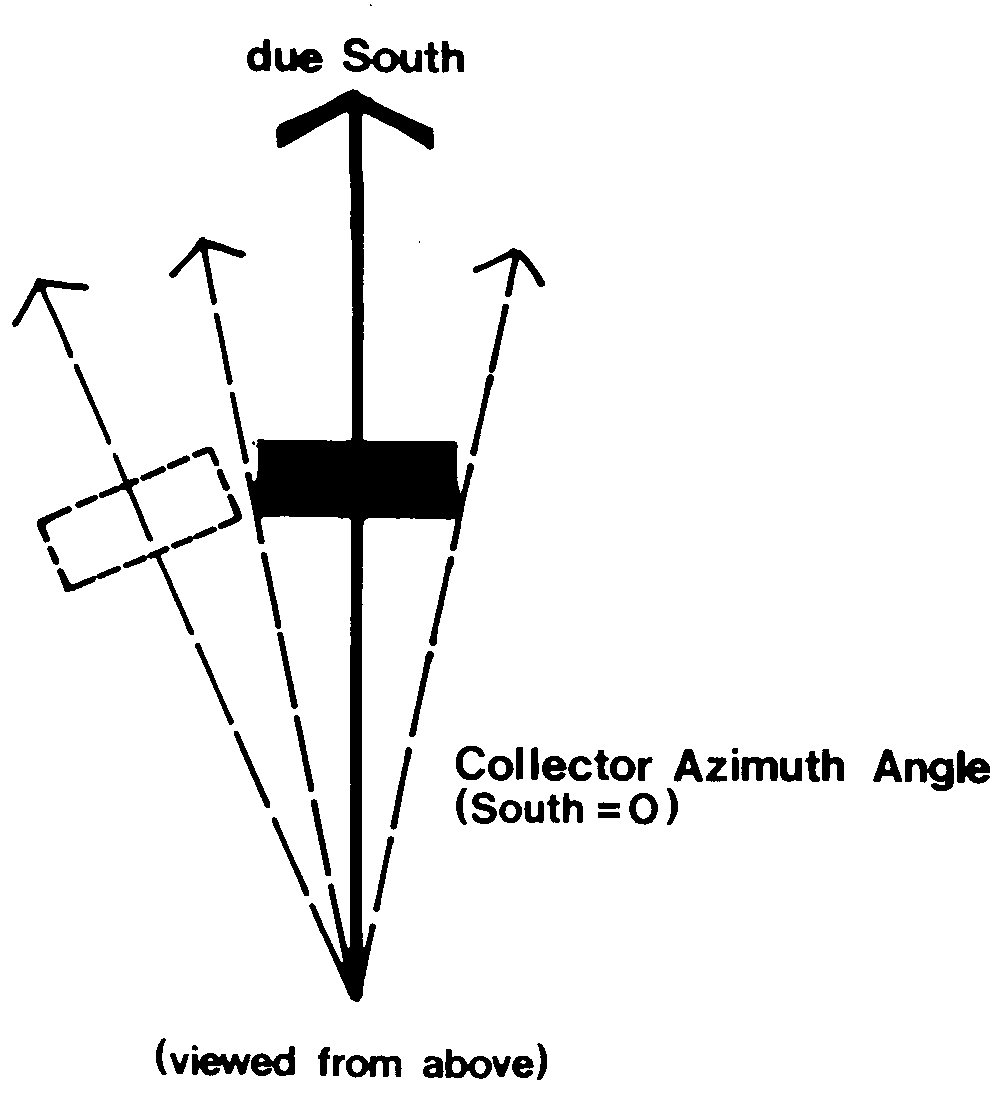

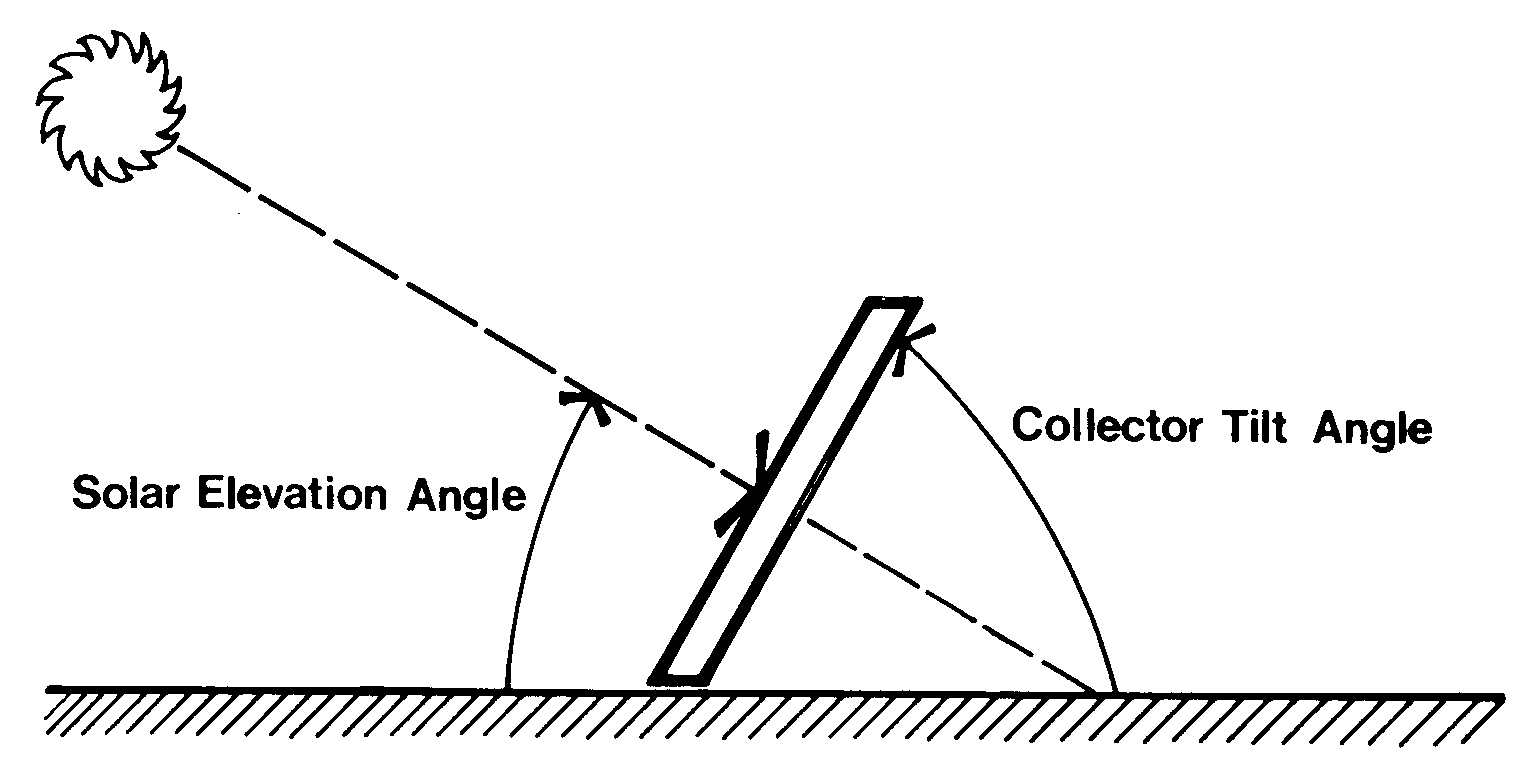

A solar collector’s performance is somewhat sensitive to the tilt of the collector from the horizontal as well as its azimuthal (east or west of south) orientation. Figures 1 and 2 indicate the important angles to consider in active solar designs. Collector tilt in Alaska depends upon the desired application. To optimize the collectors for winter time, a tilt greater than the latitude would provide optimum radiation capture. Keep in mind, however, that solar radiation is limited during the Alaska winter, so such a strategy would reduce the amount of solar energy captured on a yearly basis. A collector tilt less than the latitude optimizes for the best production on an annual basis.

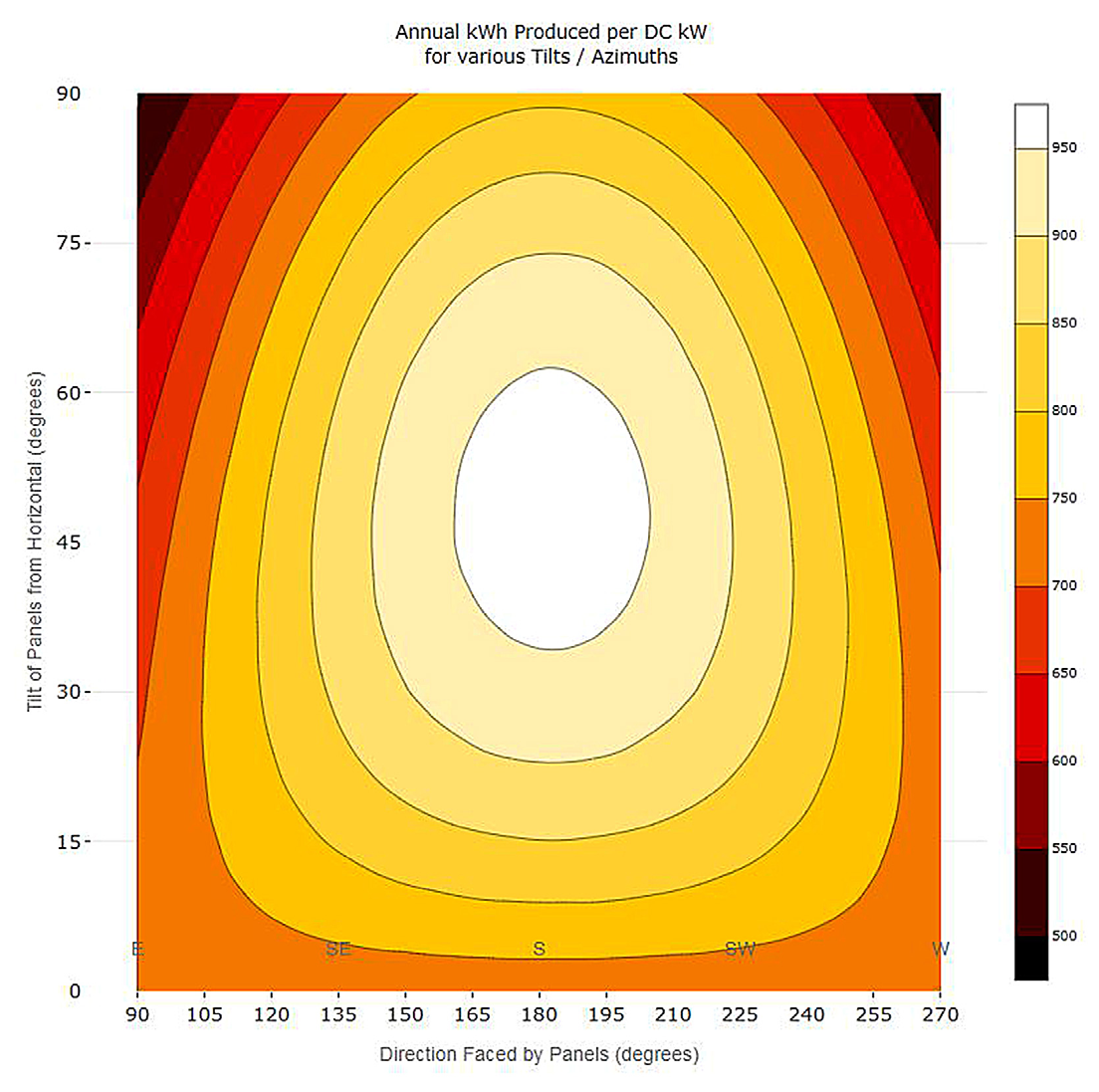

The roof is often the first place that people think of to install solar panels, and for good reason. It is a ready platform, often tilted towards the south. When considering the optimum azimuth and angle at which to install solar panels, it often comes down to a trade-off between cost and production. In most locations in Alaska, the ideal orientation to maximize annual energy output of solar electric panels is pointed due south and tilted at or slightly less than latitude. An excellent tool to demonstrate the energy output from various solar panel orientations at various locations around the state is located at this website built by Conroy Whitney using PVWatts modeling performed by Alan Mitchell: http://solar-contour-plot.conroywhitney.com/ (see illustration above).

It is often advantageous to install a system at an angle less than latitude. This is because Alaska gets such a high percentage of its sun in the summer. In addition, the website demonstrates that if a roof isn’t optimally sited, the losses from installing panels slightly east or west of south and at a pitch much less than latitude might only be a small percentage. For example, if a Fairbanks roof is facing southwest at a 25° slope, installing a PV system parallel to the roofline will result in production losses of only about 15% from optimum orientation. This may very well be a worthwhile sacrifice to avoid paying the higher racking costs to install the system at a steeper angle or different azimuth. In addition, steeper racking on roofs often leads to wind loading issues and could add additional engineering requirements to the system installation. If a steeper angle is desired to maximize winter and spring production, investigate mounting the array on a south-facing wall. These facts show that there is much more opportunity for architectural and siting variation than is normally assumed. Flat arrays, however, are not recommended in Alaska since they won’t shed snow well enough to take advantage of the spring solar resource.

Shading and Topography

Trees and shading from other buildings should be carefully reviewed on site before a final collector design is chosen. Remember that small trees become big and it could become necessary to remove them in the future to maintain good solar access. In some areas, people have negotiated solar easements from neighboring properties to ensure “solar access,” the guarantee that nothing will be constructed or allowed to grow that will shade their solar collectors.

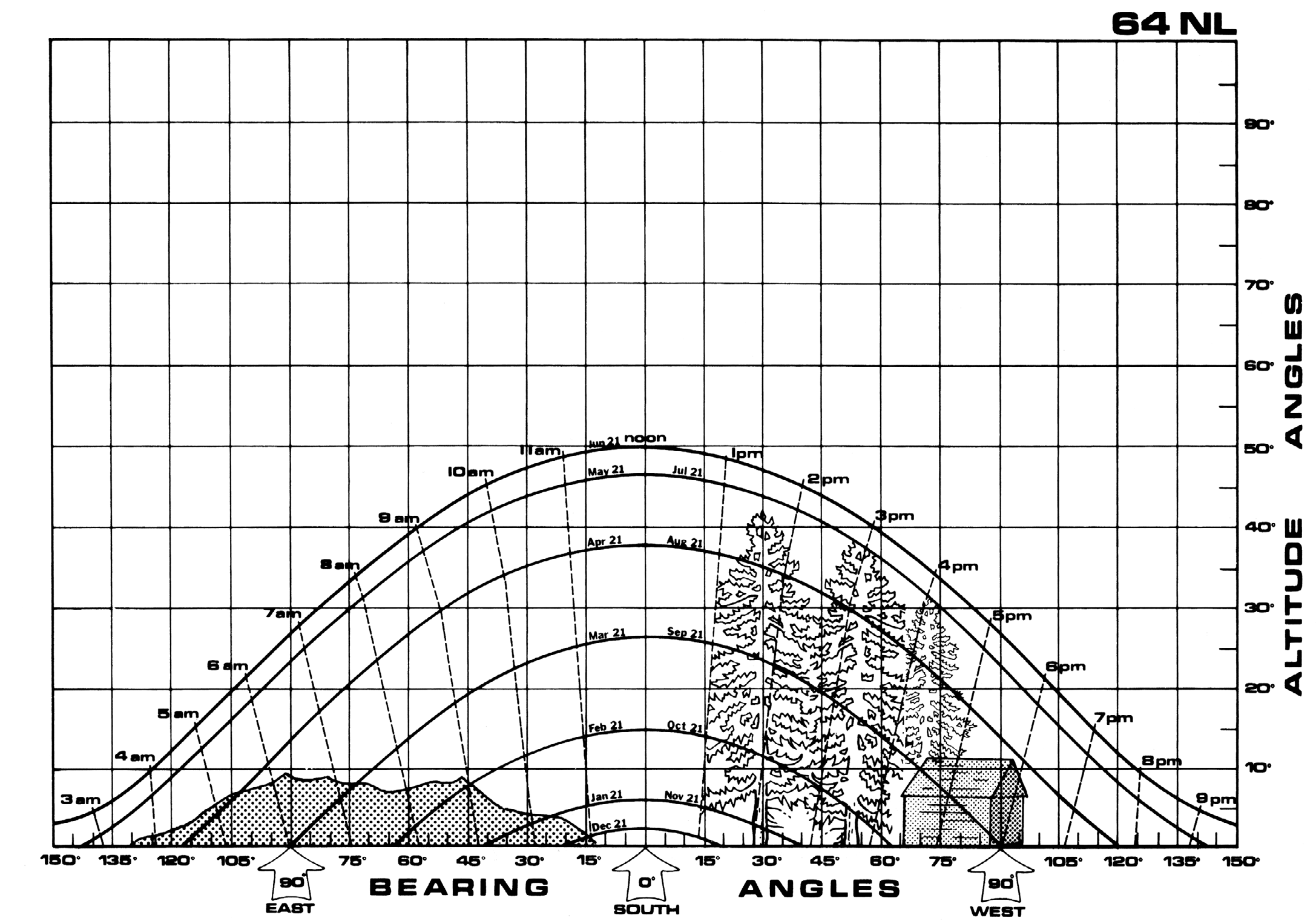

Sun Path Diagrams

It is possible to predict the position of the sun at any time. The path and the position depend on the latitude of the site. A sun path diagram is a graphic representation of the path of the sun in the sky for virtually any time of the year. This type of sun path diagram is useful for architectural insights, since a horizon can be sketched onto it to indicate solar obstructions. Sun charts for any location can be downloaded from the University of Oregon Solar Radiation Monitoring Lab website at http://solardat.uoregon.edu/SunChartProgram.html.

Sketching the horizon onto the chart enables the prospective solar user to identify the major obstructions that will shade the collector from the sun in their true angular perspective. In the early days of solar PV technology, a hand level was used to get the angular elevations of obstacles. With the advent of smart phones, however, there are a number of apps, such as the Sun Surveyor app, that identify the angle and azimuth of solar obstructions, which can easily be traced onto a sun path chart.

In Figure 3, the trees are the major obstruction. Identifying such obstructions by location can also indicate how much sun is actually blocked by the obstruction. Let us examine the situation in March. Using the March 21 sun path for Fairbanks, Alaska, we can see what happens during the day. Beyond 74° east of south, the sun is blocked by the hills to the southeast of the site, so sunrise is delayed until the sun clears the hills. This delay is 1 hour 20 minutes on March 21. From 7:20 a.m. until 1:20 p.m., the sun is unobstructed. The trees to the southwest of the site obstruct the sun during the entire afternoon; the site gets virtually no direct afternoon sun after 1:20 p.m.

This can be quantified by downloading the hourly data for your location from PVWatts.

The hourly production for periods where shading will occur can be corrected in an Excel document from the original PVWatts estimate. For example, if the sun chart shows that shading will occur every day in March before noon, all of the PVWatts estimates can be corrected as appropriate to show little or no output before noon on March.

This suggests the need to do whatever one can to remove significant obstructions. Increasing the size of the collection area is also an option that could be worth exploring.

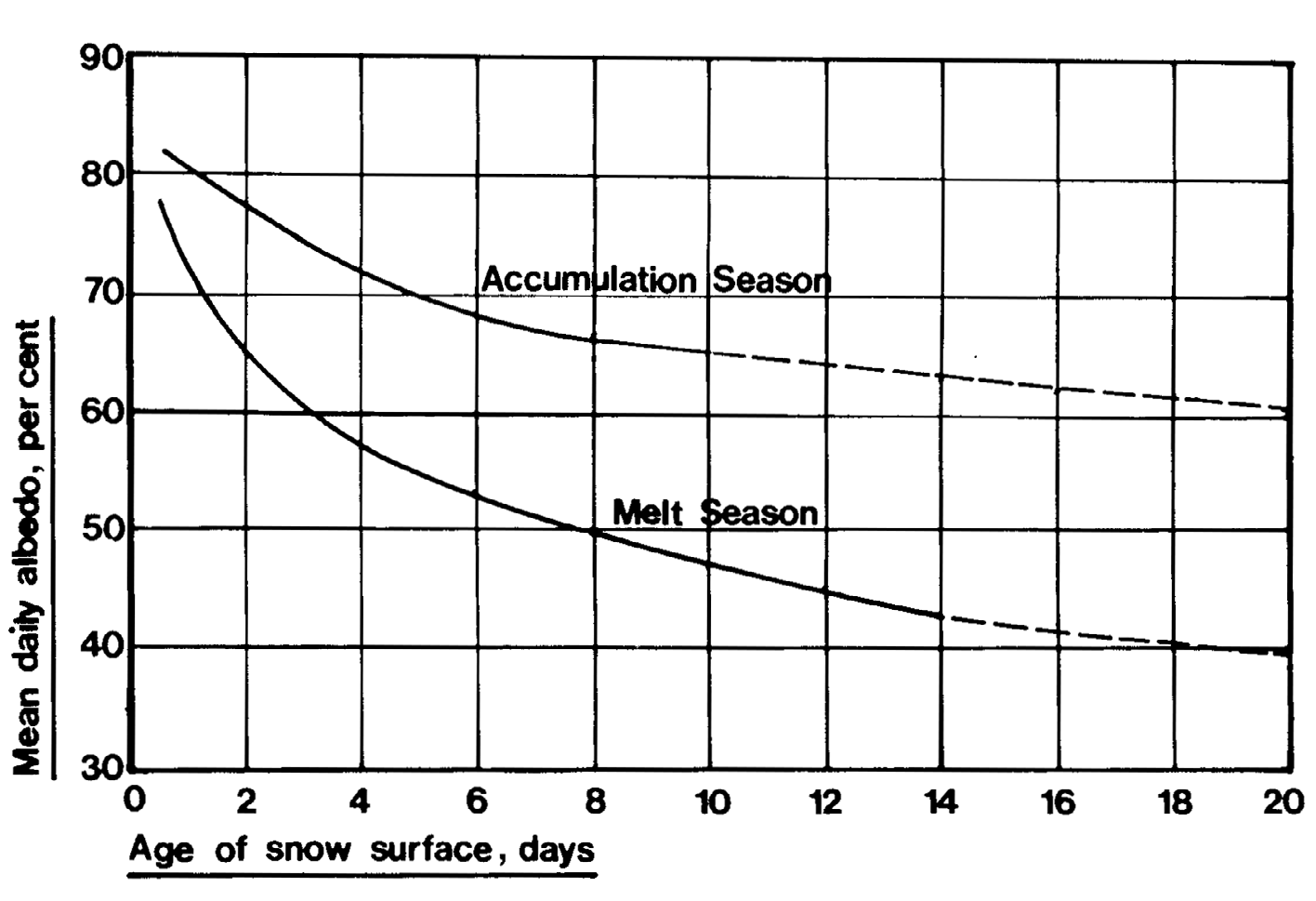

Snow Cover Effects

A positive factor for solar energy capture in Alaska is the seasonal snow cover. As can be seen in Figure 4, new snow has a reflectivity (albedo) of 70% to 80%. This is four times the reflectivity of normal ground cover. In effect, snow acts as a very efficient mirror, reflecting additional radiation onto the collector. Research suggests that snow cover can enhance the collection of solar energy from 15% to 30%. This has been solidly confirmed in Alaska, even for years that are much cloudier than normal (Seifert, 1983).

Solar PV Modeling Best Practices

Modeling PV output is an important part of the planning process. Over the last several decades, solar PV models have improved and these models are now able to accurately calculate the output of a PV array in various weather conditions. The most common and easiest-to-use model for estimating the electrical output of a solar PV system is PVWatts. It was created by the National Renewable Energy Lab and is available free of charge on its website and includes standard representative weather files for certain regions. A general understanding of the model inputs and outputs is helpful to better understand the conditions that effect the output of a solar PV system. The equation that PVWatts uses when the plane of array irradiance is greater than 125 W/m2 is shown below(Dobos, 2014):

Pmp = Ee / E0 Pmp0 [1 + γ (Tc - T0)]

Where:

Ee is the effective irradiance

- E0 is the reference irradiance (1000 W/m2 )

- Tc is the PV cell temperature

- T0 is the reference temperature (25°C)

- Pmp is the maximum power point

- Pmp0 is the reference rated output of the panel

- γ is the temperature correction for maximum power (Values range from -0.47 %/°C to -0.35 %/°C for crystalline modules) PVWatts uses a slightly different equation at low irradiance levels, but for the sake of simplicity we will focus on the equation above.

Each of the variables above includes a variety of other inputs. For example, the PV cell temperature is not the same as the ambient temperature. Total incident POA (plane of array) irradiance, wind speed, and dry bulb temperature are used to calculate the operating cell temperature. Similarly, “effective” irradiance is the amount of irradiance that is available for conversion to electrical current. It includes losses from reflections (function of angle of incidence), soiling or snow on the module surface, and spectral mismatch.

If you are interested in learning more, you can review the PVWatts Version 5 manual at http:// pvwatts.nrel.gov/downloads/pvwattsv5.pdf.

The Sandia National Lab PV performance modeling collaborative (PVPMC) website also has detailed descriptions of the equations that underlie the PVWatts model and information about how to calculate cell temperature and effective irradiance: https://pvpmc.sandia.gov/

The PVWatts model is a very general (yet proven) modeling toolset that is adequate for most residential situations. If more detailed modeling is necessary — e.g., inclusion of shading effects, distinguishing between different module and inverter models, oversizing of the DC array relative to the inverter capacity, etc. — there are additional free modeling tools that include the SAM (System Advisor Model) from NREL and the PVLIB Toolbox available at the PVPMC website above.

When using any modeling tool, it is important to consider multiple input data sources (e.g., weather files). For example, PVWatts has six different weather data sets to choose from in the Anchorage area. While solar resource can vary significantly over short distances because of microclimates, there is also a significant variability in the quality of the weather data sets that are available, and it is always advisable to run predictions using several nearby sites to estimate uncertainties. For example, in Anchorage, the Birchwood weather data set shows a significantly higher solar resource than the other data sets in the area and may be overestimating system output. Users should take the time to use multiple data sets to quantify possible uncertainty. If they disagree by a large margin, more investigation will likely be necessary and a more conservative estimation about a system output might be warranted.

Publicly Available Solar Resource Datasets

There are generally two solar radiation datasets referenced in this report, the National Solar Radiation Database and the NASA Surface Meteorology and Solar Energy Dataset. There are many other models that derive irradiance at the Earth’s surface from satellite data, but these are the most widely available for Alaska.

NASA Surface Meteorology and Solar Energy Data Set

NASA’s Prediction of Worldwide Energy Resource (POWER) has a goal to observe, understand, and model the Earth system to discover how it is changing, to better predict change, and to understand the consequences for life on Earth. Included in this project is the Surface meteorology and Solar Energy (SSE) project. The SSE project was initiated to provide internet-based access to parameters specifically tailored to assist in the design of solar- and wind-powered renewable energy systems.

Data access and a description of the SSE dataset can be found here.

This dataset is used by the modeling programs Homer and RetScreen. The SSE dataset was also used by NREL to develop the irradiance maps shown in the introduction of this manual and is considered the most accurate publicly available dataset for locations north of 60 degrees latitude.

The solar radiation data is derived from satellite observations and meteorological data from the Goddard Earth Observing System assimilation model. A detailed description of the modeling used to develop this data set can be found here at NASA Power. National Solar Radiation Database (NSRDB)

The National Solar Radiation Database is a collection of meteorological and solar irradiance datasets for locations around the world. It was first released in 1979 and the most recent release occurred in 2015. Initially the dataset contained was derived from land-based measurements, but ground-based solar measurements are hard to take and extremely expensive. With each subsequent release, the dataset has grown and contains a higher percentage of modeled sites. Starting with the 2007 release, the dataset consisted only of modeled locations. The 2015 release includes half-hour satellite-modeled solar data for 1998-2014 on a 4 km grid. It covers 23°W to 175°W and 20°S to 60°N. North of 60°N the satellite-modeled solar data becomes unreliable. Unfortunately, Anchorage lies at about 60°N so most of Alaska is not included in this latest release. PVWatts cannot use the newest NSRDB in Alaska, but one can still use the older typical meteorological year (TMY) data which is available for various points around Alaska. TMY2 data, which contains more measured sites, tends to be more accurate if it is available near the desired location. The NSRDB can be accessed at NSRDB: National Solar Radiation Database.

Basic Solar PV System Components

Sanchez and Woofenden (2011)

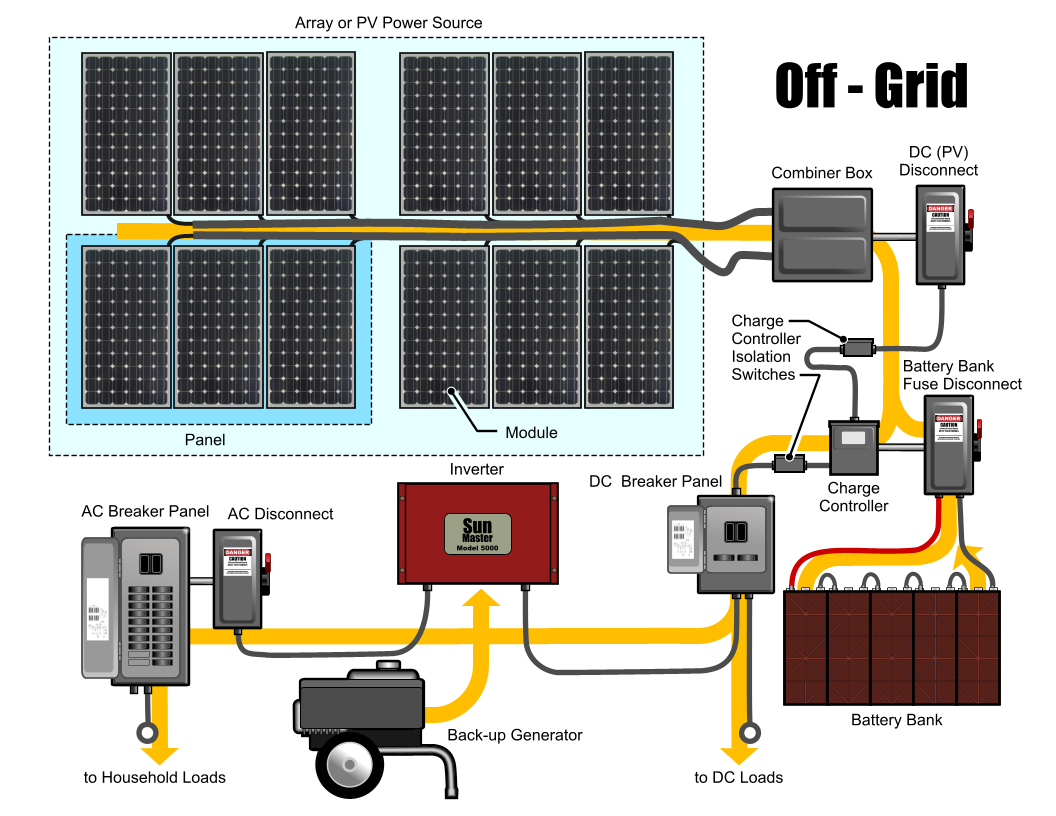

This section briefly discusses the different components of a basic off-grid and grid-tied PV system and how they work together. Solar PV technology has gone through many changes since this guide was last updated 10 years ago. In general, the newer components fit together more easily and are designed so that the system is simpler, with reduced labor and installation times. In addition, codes at the local, state, and national level continue to change and become more robust and detailed. The components described throughout this guide are continually evolving to comply with these tougher and more complicated guidelines.

Understanding the basic components of a solar PV system and how they function is not an overwhelming task but it does require some study. Following are some brief descriptions of the common equipment used in grid-intertied and off-grid solar-electric systems. Systems vary and not all the equipment described here is necessary for every system type.

Solar-Electric Panels, aka Photovoltaic (PV) Panels

PV panels are a solar-electric system’s defining component, where sunlight is used to make direct current (DC) electricity. Behind a PV panel’s shimmering facade, wafers of semiconductor material work their magic, using light (photons) to generate electricity through what’s known as the photovoltaic effect. Other components in your system use the electricity generated by your solar-electric panels to safely power your electric loads, such as lights, computers, and refrigerators.

Electrical Terminology

Before we go any further we need to define some terms. For our purposes a few simple definitions are all we need.

Voltage is the difference in potential energy. Think of the difference between the positive (+) and the negative (-) terminals on a car battery. For example: if you connected a volt meter across the posts on a car battery the meter would normally indicate about 12 volts.

Amperage or electrical current refers to the electrical charge carried by moving electrons. In our case these electrons are flowing over a wire.

Power is defined as the rate at which electrical energy is transferred, and the unit that power is normally expressed in is the watt (W).

The way these three items relate to each other can be shown by the equation

Power (watts) = V (volts) x A (amps)

Watt-hour pertains to the usage of power over time. For example if you leave our 1 watt light bulb on for a period of 1 hour you will have used 1 watt-hour of energy. Watts X amps = watt-hours (Wh). If you pay an electric bill you may be familiar with the term kilowatt-hour (kWh). A kWh is equal to a thousand W-h.

Amp-hour also pertains to the usage of power over time. It’s included here because storage batteries are rated in amp-hours. If you power a 1 amp load for a period of 1 hour you have one less amp hour in your battery.

PV panels are assigned a rating in watts based on the maximum power they can produce under a standard sun and temperature condition. You can use the rated output to help determine how many panels you’ll need to meet your electrical needs. Multiple modules combined together are called an array.

Recently, some panels have been marketed as AC panels. These panels have a microinverter integrated into them that converts the DC electricity into AC current.

Most panels in use today are made from silicon and can be divided into two types: monocrystalline silicon and polycrystalline silicon panels, which are made of the same materials with different manufacturing processes. Monocrystalline panels are more efficient and more expensive. In addition, it is generally accepted that they perform better in low light conditions. Examples of both are shown in Figure 5.

In addition to silicon PV cells, the thin-film process is gaining market share as the technology continues to improve and the price drops. The different types of thin-film solar cells can be categorized by which photovoltaic material is deposited onto the substrate. Photovoltaic materials include amorphous silicon, cadmium telluride, copper indium gallium selenide, and organic photovoltaic cells. Depending on the technology, thin-film modules have efficiencies around 10%; however, there is continued hope for higher efficiencies in the future.

A rigid panel made of silicon is the most common form of solar collector, but PV technology has also been integrated into roofing shingles and tiles and even peel-and-stick laminates. These technologies are still in the emerging stages.

PV modules are designed to withstand severe weather, including extreme heat, cold, and hail-stones. All reputable PV panels should have at least a 25-year warranty. While some degradation in power output over time is normal, consumers should look for some kind of performance guarantee over time. Most reputable manufactures will guarantee that after 25 years actual power output will be no less than 80% of the original labeled output. For example, the warranties from Canadian Solar are shown in Table 1.

Table 1. The Canadian Solar module warranty (shown below) covers a period of 25 years. All reputable solar PV modules should have a similar warranty for at least 25 years.

Polycrystalline Module Products

During the first year, Canadian Solar warrants the actual power output of the module will be no less than 97.5% of the labeled power output.

From year 2 to year 25, the actual annual power decline will be no more than 0.7%; by the end of year 25, the actual power output will be no less than 80.7% of the labeled power output.

Monocrystalline Module Products

During the first year, Canadian Solar warrants the actual power output of the module will be no less than 97% of the labeled power output

From year 2 to year 25, the actual annual power decline will be no more than 0.7%; by the end of year 25, the actual power output will be no less than 80.2% of the labeled power output.

*Source: Canadian Solar

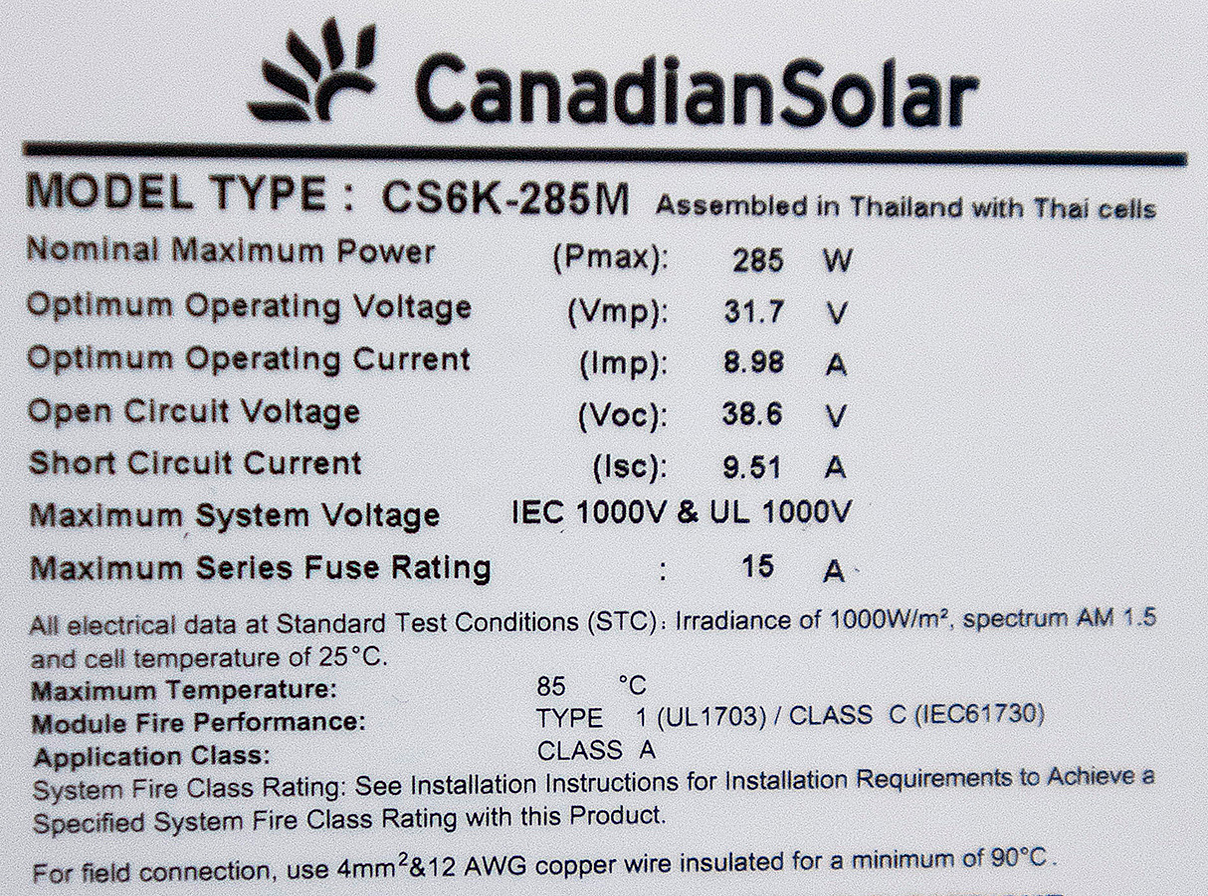

Solar modules have certain electrical characteristics that must be considered when designing a grid-connected system. For instance, solar modules produce the highest voltages when they are exposed to sunlight but are not generating electricity. This counterintuitive phenomenon is called open-circuit voltage, or Voc. Solar modules also produce higher voltage when they are cold. The image in Figure 6 shows a specification label for a 285 W monocrystalline module manufactured by Canadian Solar.

Looking at Figure 2 you can see that the open-circuit voltage (Voc) is 38.6 VDC but the rated voltage (Vmp) is listed at 31.7 VDC. For example, say we have a 3,000 W inverter and we want to string 10 of these 285 W solar modules together. The minimum operating voltage for the inverter we’ve chosen is 250 VDC. It looks like 10 modules in series will give us about 317 VDC, so it looks like we’re in good shape there. If the maximum voltage listed on the inverter is 500 VDC, then ten modules in series should give us about 386 VDC during open-circuit conditions according to the label.

Notice that the solar cell temperature at Standard Test Conditions is 25°C. In places like Fairbanks it can get a lot colder than 25°C and still be very sunny out so if we assume a low temperature of -40ºC we have to multiply the Voc by 1.25 according to the National Electric Code. When we multiply 386 VDC by the correction factor of 1.25 we now have 483 VDC. This would keep us safely below the 500 VDC limit.

Referencing Figure 6 again, we can see that the module has a short-circuit current (Isc) of 9.51 amps and an optimal operating current (Imp) of 8.98 amps. If we multiply the Vmp of 31.7 volts by the Imp of 8.98 amps we get 285, which is the rating of the module at standard test conditions (STC).

Array Mounting and Racking

Mounting racks provide a secure platform on which to anchor PV panels in place and orient them correctly. Panels can be mounted in one of three locations:

- On a rooftop (roof-mounted) (Figure 7)

- Atop a steel pole set in concrete (pole mounted) (Figure 8)

- At ground level (ground mounted) (Figure 9)

The specific pieces, parts, and materials of the mounting device will vary considerably depending on which mounting method is choose.

Usually, arrays in urban or suburban areas are mounted on a home’s south-facing roof, parallel to the roof’s slope. This approach is sometimes considered most aesthetically pleasing and is usually the least expensive. Manufactures have designed a wide range of flashing and attachments designed to provide leak-free mounting attachments for every conceivable type of roof. In areas with space or orientation constraints, pole- or ground-mounted arrays are another choice.

Solar module racking has come a long way over the last decade. Modern racking designs are more robust and easier to install than they were in the early days of solar PV. Racking comes pre-engineered for a variety of snow and wind-loading conditions and can be designed to customer-specific situations through the use of online company portals. One major advancement that PV racking has made is the integration of equipment grounding systems into the racking design, which save installers time and materials compared to the early days of having to run copper grounding wire between each module frame and rail. Some of the major brands that consumers may encounter during their research include Iron-Ridge, SnapNrack, and Unirack. These are just a few of the many types and brands of racking available.

There are a couple of issues to be aware of when it comes to racking. Some people who have installed solar PV in Interior Alaska, where swings in temperatures between the winter lows and summer highs can reach 150°, have reported that they prefer steel racking as opposed to the more common aluminum racking because of concerns with expansion and contraction. Aluminum expands and contracts up to 30% more than steel. At the very least, if solar is being installed in this climate, installers should check with the racking manufacture and use Nylock hardware when possible.

Trackers

Pole-mounted PV arrays can also incorporate tracking devices that allow the array to automatically follow the sun across the sky from east to west each day. Tracked PV arrays can increase the system’s daily energy output by 25% to 40% (Colgan et al., 2010).

In the early days of PV, modules were by far the most expensive part of a system. For this reason, it was necessary to maximize the energy production of each module throughout every part of the year to maximize system production and minimize cost. More recently, however, the price of modules has fallen dramatically. One of the greatest advantages of solar PV is the lack of moving parts. When a tracker is used in a system it adds complexity and an additional way for the system to fail. For this reason, most installers steer customers away from using trackers and instead encourage the installation of additional modules.

Some customers have successfully used manually adjustable pole-mounted arrays to minimize system complexity while maximizing production by manually changing the array tilt angle a couple times each year. An example is shown in Figure 10.

Adjustable mounting racks enable someone to set the angle of the PV panels seasonally, keeping them aimed more directly at the sun. In addition, the steep winter angles facilitate snow shedding. While systems like this will likely cost slightly more to install, they could be advantageous in certain situations. Customers should consider their own situation and constraints.

Inverter

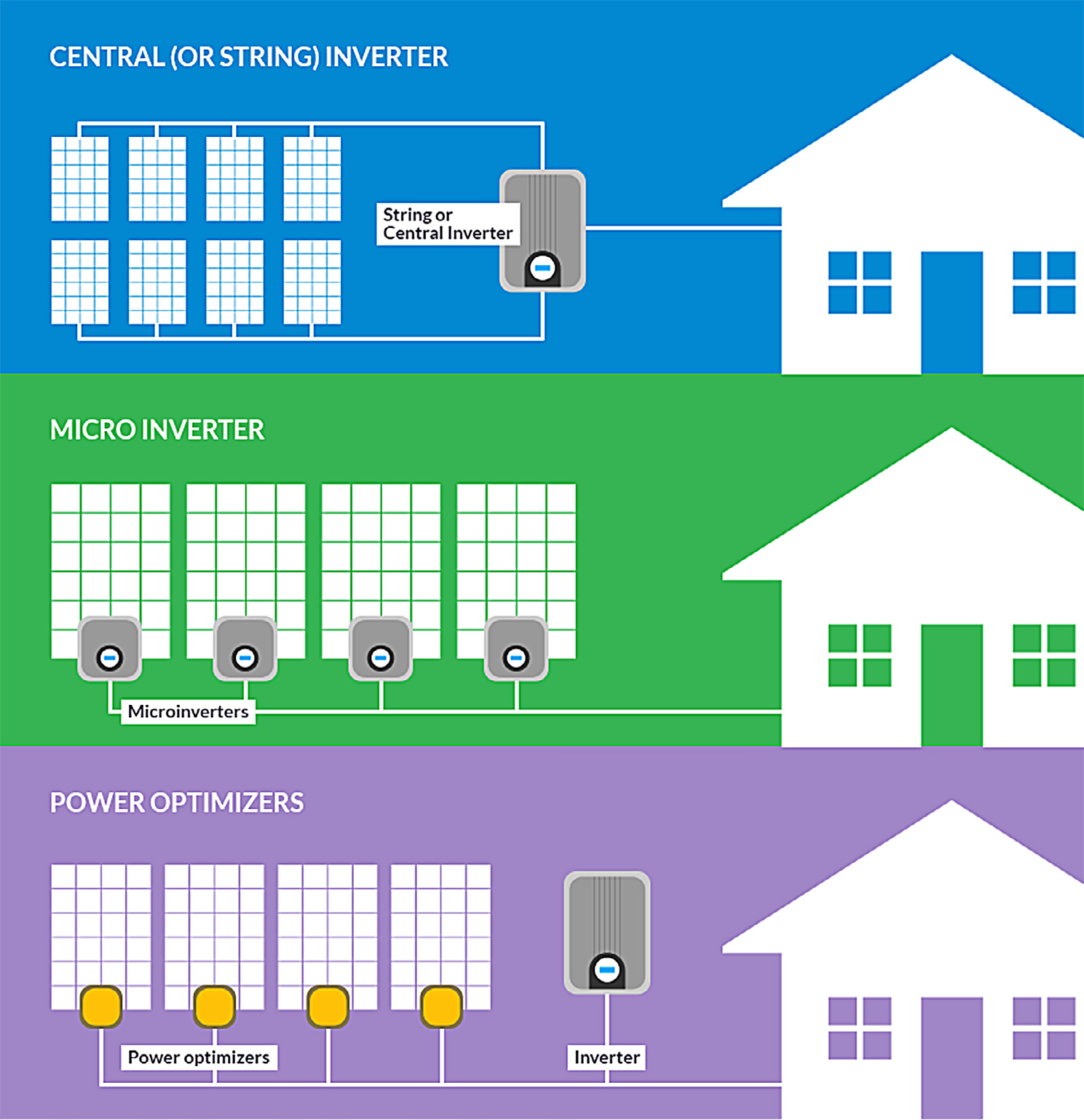

As explained earlier, PV panels produce DC electricity. Inverters transform the DC electricity produced by PV modules into the alternating current (AC) electricity commonly used in most homes for powering lights, appliances, and other gadgets. Grid-tied inverters synchronize the electricity they produce with the grid’s utility-grade AC electricity, allowing the system to feed solar-made electricity to the home and back to the utility grid when the PV system is producing more electricity than the home is using at that moment. Grid tied inverters have a variety of safety features built into them to protect the grid and the utility staff that maintain it. When there is a power outage or power falls outside of established parameters, the inverters will shut down to prevent electricity from flowing onto the grid when the power is out and linemen might be making repairs.

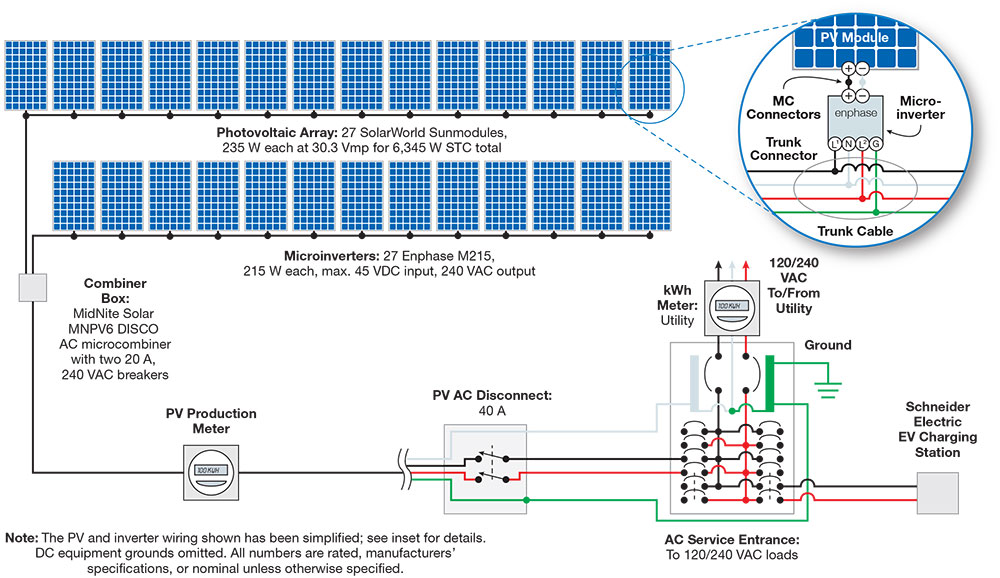

Microinverter — A small weatherproof inverter installed behind each solar module. Converts the DC power generated by the solar panel into AC power right at the panel.

String Inverter — Also called a central inverter. With these, solar panels are connected together into strings and the DC power is wired to a large inverter in a central location. It converts the power for all the modules at once.

Grid-tied inverters have experienced significant improvements over the last decade and can generally be broken into two categories, microinverters and central inverters (sometimes called string inverters).

The first commercially successful microinverters where introduced by Enphase in 2008. A newer Enphase microinverter is shown in Figure 11. There are now many manufactures that produce micro inverters for a variety of situations and system types. They usually attach to the racking directly behind the PV panel.

When a central inverter is used (Figure 12), the PV panels are wired together in parallel and series, and high-voltage DC power is sent to the inverter, where it is converted to AC power. A single central inverter is typically used for a single system unless the PV installation is large. Central inverters are used for off-grid battery-based systems.

Many grid-tied central inverters also use what are called DC optimizers. Typically, a single optimizer is connected to each panel. The optimizers are a DC-to-DC converter technology developed to maximize the energy harvest from the PV modules. A simple diagram of each inverter type is shown in Figure 13.

Most grid-tie inverters are designed to operate without batteries, but battery-based models also are available. Battery-based inverters for off-grid or grid-tie applications often include a battery charger that is capable of charging a battery bank from either the grid or a backup generator during cloudy weather.

Most grid-intertie inverters are rated for outdoor installation while most off-grid inverters are not weatherproof and should be mounted indoors, close to the battery bank.

Battery Bank

PV panels will produce electricity whenever the sun shines on them, but if the system is off-grid, it will need a battery bank — a group of batteries wired together — to store energy so electricity is available at night or on cloudy days. For off-grid systems, battery banks are typically sized to keep household electricity running for one to three cloudy days.

Grid-intertied systems can also include battery banks to provide emergency backup power during blackouts.

Although similar to ordinary car batteries, the batteries used in solar-electric systems are specialized for the type of charging and discharging they’ll need to endure. Lead-acid batteries are the most common battery used in solar-electric systems. Flooded lead-acid batteries are usually the least expensive, but they need distilled water occasionally to replenish the water lost during the normal charging process. Sealed absorbent glass mat (AGM) batteries are maintenance-free and designed for grid-tied systems where the batteries are typically kept at a full state of charge. Gel-cell batteries can be a good choice to use in unheated spaces because of their freeze-resistant qualities. Li-ion batteries are quickly gaining market share and several manufacturers, including Enphase and Tesla, are designing wall-mounted lithium-ion batteries. These are just a few of the different types of batteries available. Storage is one of the fastest growing aspects of distributed renewable energy generation and will likely revolutionize the grid within a generation.

A lead-acid battery (left) and a lithium-ion battery are shown above. While lithium ion technology is new to the solar industry, deep-cycle lead-acid batteries have been a mainstay of off-grid PV systems for years. Source: www.solarpro.com

Disconnects, Fuses, and Wiring

The DC disconnect is used to safely interrupt the flow of electricity from the PV array for all systems except those using microinverters. It is installed between the panels and the inverter and is an essential component when system maintenance or troubleshooting is required. The disconnect enclosure houses an electrical switch rated for use in DC circuits. It also may integrate either circuit breakers or fuses, if needed.

Charge Controllers

A charge controller is used in off-grid systems. Its primary function is to protect the battery bank from overcharging. It does this by monitoring the battery bank — when the bank is fully charged, the controller interrupts the flow of electricity from the PV panels. Batteries are expensive and must be used according to certain specifications. To maximize their life span, a charge controller avoids overcharging or undercharging them.

Most modern charge controllers incorporate maximum power point tracking (MPPT), which optimizes the PV array’s output, increasing the energy it produces. Many battery-based charge controllers also include a low-voltage disconnect that prevents over discharging, which can permanently damage the battery bank.

System Meter, AKA Battery Monitor, Amp-Hour Meter

System meters measure and display several different aspects of your solar-electric system’s performance and status, tracking how full your battery bank is, how much electricity your solar panels are producing or have produced, and how much electricity is in use. Operating your solar-electric system without metering is like running your car without any gauges — although possible to do, it’s always better to know how much fuel is in the tank. System metering is recommended for both off-grid and grid-tied PV systems.

Main DC Disconnect

In battery-based systems, a disconnect between the batteries and the inverter is required. This disconnect is typically a large, DC-rated breaker mounted in a sheet-metal enclosure. This breaker allows the inverter to be quickly disconnected from the batteries for service and protects the inverter-to-battery wiring against electrical fires.

AC Breaker Panel and Inverter AC Disconnect

The AC breaker panel is the point at which all of a home’s electrical wiring connects with the “provider” of the electricity, whether it is the utility grid or a solar-electric system. This wall-mounted panel or box is usually installed in a utility room, basement, or garage, or on the exterior of the building. It contains a number of labeled circuit breakers that route electricity to the various rooms throughout a house. These breakers allow electricity to be disconnected for servicing and also protect the building’s wiring against electrical fires.

Just like the electrical circuits in your home or office, an inverter’s electrical output needs to be routed through an AC circuit breaker. This breaker is usually mounted inside the building’s main panel, which enables the inverter to be disconnected from either the grid or from electrical loads if servicing is necessary, and it also safeguards the circuit’s electrical wiring.

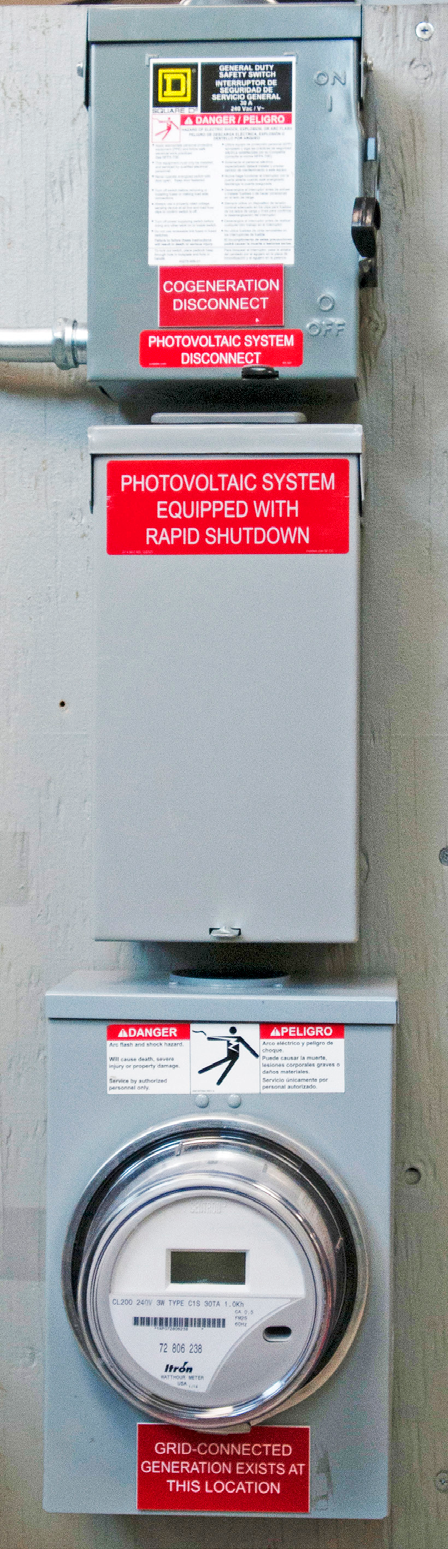

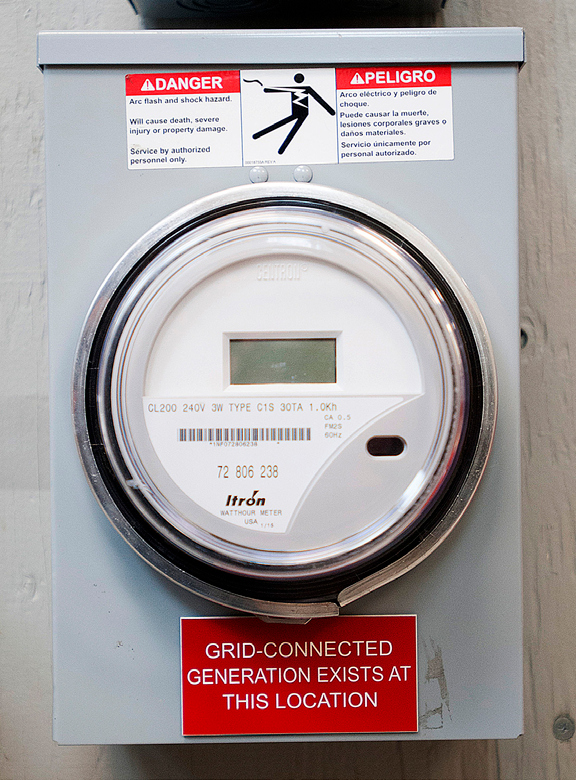

Additionally, utilities will require a lockable AC disconnect between the inverter and the grid that is used by emergency responders or utility personnel. These are usually located in an easily accessible area near the utility KWH meter.

Utility Kilowatt-Hour Meter

Most homes with a grid-tied solar-electric system will have AC electricity both coming from and going to the electric utility grid. A bidirectional KWH meter can simultaneously keep track of how much electricity flows in each of the two directions to monitor how much electricity is being used and how much the solar-electric system is producing. The utility company often provides intertie-capable meters at no cost.

Backup Generator

Off-grid solar-electric systems can be sized to provide electricity during cloudy periods. But sizing a system to cover a worst-case scenario, like several cloudy weeks during the winter, can result in a very large, expensive system that will rarely get used to its capacity. To save money, size the system moderately but include a backup generator to get through those occasional sunless stretches.

Engine generators can be fueled with diesel, gasoline, or propane, depending on the design. These generators produce AC electricity that a battery charger (either stand-alone or incorporated into an inverter) converts to DC energy, which is stored in batteries. A well-designed solar-electric system will require running the generator only 50 to 200 hours a year.

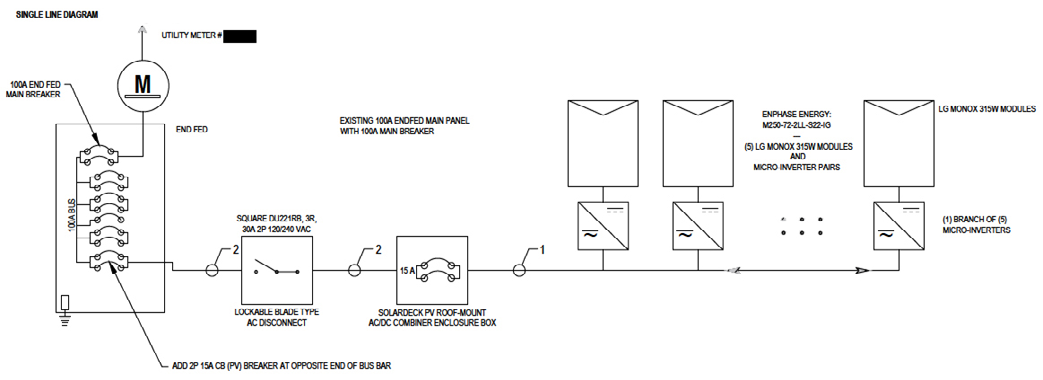

Solar-Electric Systems Demystified

As you can see, the anatomy of a photovoltaic system isn’t that complicated. All of the parts have a purpose, and once you understand the individual tasks that each part performs, the whole thing makes a bit more sense. Figure 14 on the next page shows schematics of completed systems. In addition, solar home tours are held each spring in many cities and towns throughout Alaska. Seeing solar PV systems first hand is great way to learn more about renewable energy systems and meet the people who are using renewable energy in your area.

Current Standards and Codes

The codes and standards associated with solar PV are numerous and are continually evolving and changing. They come from a variety of organizations, including Underwriters Laboratories (UL), the National Fire Protection Association (NFPA), which publishes the National Electric Code (NEC), and the Institute of Electrical and Electronics Engineers Standards Association, which publish the Institute of Electrical and Electronics Engineers (IEEE) standards. The goal of these standards as they relate to solar PV is to ensure the safety of homeowners, installers, emergency responders, and utility personnel.

This section attempts to make some sense out of the alphabet soup of acronyms while briefly describing each of the organizations listed above and how they all fit together. According to the NFPA: “A standard tends to be a more detailed elaboration. A code tells you what to do, and a standard tells you how to do it.” This basic distinction holds true for equipment standards, like UL 1703 or UL 1741, which essentially tell manufacturers how to construct flat plate PV modules and inverters, charge controllers, and combiner boxes and how to test the equipment to ensure product safety.

The most common codes and standards associated with solar PV that readers will encounter include:

- UL 1741: The standard for inverter compliance with grid interactive functions such as anti-islanding in the event of a grid failure.

- UL 1741-SA: A revised version of UL 1741 that incorporates supplement A (thus the SA abbreviation). It includes inverter testing related to anti-islanding, high/low voltage ride through, high/low frequency ride through, ramp rates, and many other factors.

- IEEE 1547: The widely adopted standard for interconnecting a rooftop PV system to the electric grid. Key provisions in IEEE 1547 include voltage and frequency trip thresholds, disconnection, grounding, monitoring, and islanding requirements.

- California Rule 21: A tariff that describes the interconnection, operating and metering requirements for generating facilities to be connected to a utility’s distribution system in California (Rule 21 Interconnection). Best known for the smart inverter requirements. Parts of this tariff will likely be applied in other regions in the future as solar penetrations increase.

- Article 690 of the National Electric Code: This is the main section in the NEC; it details the installation of distributed solar PV systems. One of the most referenced sections is 690.12, the rapid shutdown of PV systems on buildings. It details how parts of PV system must be de-energized when disconnected from the grid.

The following section contains excerpts from “Standards and Requirements for Solar Equipment, Installation, and Licensing and Certification: A Guide for States and Municipalities” was published in February 2017 by Beren Argetsinger and Benjamin Inskeep with funding from the U.S. Department of Energy Sun Shot Initiative and the Clean Energy States Alliance

The National Electric Code

The National Electrical Code (NEC) provides electrical safety design, installation, and inspection requirements. The NEC is sometimes referred to as NFPA 70. It was developed by the National Fire Protection Association (NFPA) and is updated every three years. Alaska is currently operating off of the 2014 NEC. The NEC devotes two of its articles to addressing solar PV systems: Article 690, Solar Electric Systems, and Article 705, Interconnected Electrical Power Production Sources.

Inverter Interconnection Standards

The tables below show some of the inverter disconnect requirements under the various standards. One can see how these requirements have evolved from the Initial IEEE 1547 to the California Rule 21. Many new inverters have grid power quality standards that can be changed with permission from the utility.

Initial IEEE 1547 interconnection standards

(IEEE Standards Association. 1547-2003-IEEE Standard for Interconnecting Distributed Resources with Electric Power Systems; IEEE Std.: Piscataway Township, NJ, USA, 2003)

The Energy Policy Act of 2005 set IEEE 1547 as the national standard for interconnecting rooftop solar PV systems and other distributed generation resources to the grid, and many states and utilities have adopted IEEE 1547 as part of their interconnections standards. Some basic details found in IEEE 1547 are discussed below. Voltage

The system shall detect the effective voltage. When any voltage is in a range given in Table 2, the distributed generation shall cease to energize within the clearing time as indicated. Clearing time is the time between the start of the abnormal condition and the distributed generation ceasing to energize the electric power system (EPS).

| Voltage Range (% of base voltages as stated in ANSI C84.1-1995) | Clearing Times (Sec) |

|---|---|

| V < 50 | .16 |

| 50 ≤ V ≤ 88 | 2.00 |

| 110 < V <120 | 1.00 |

| V ≥ 120 | .16 |

Frequency

When the system frequency is in a range given in Table 3, the distributed generation shall cease to energize the area electric power system within the clearing time as indicated. Clearing time is the time between the start of the abnormal condition and the distributed resource ceasing to energize the Area EPS. For distributed energy resources (DER) less than or equal to 30 kW in peak capacity, the frequency set points and clearing times shall be either fixed or field adjustable. For DER greater than 30 kW, the frequency set points shall be field adjustable.

| Frequency Range (Hz) | Clearing Times (Sec) |

|---|---|

| >60.5 | .16 |

| <59.3 | .16 |

California Rule 21

California Rule 21 is a tariff that establishes new requirements for connecting DR to the California grid. The goal of Rule 21 is to allow increasing amounts of DER to connect to the grid while minimizing the negative effects of the non-firm production. The first phase went into effect on September 9, 2017 in California. Tables 4 and 5 describe the basic voltage and frequency parameters that Rule 21-compliant inverters must meet. We discuss California Rule 21 here because it may very well become the next step for the interaction between distributed generation facilities and utilities where high penetrations of solar PV exist. In Alaska, it can provide guidance in the rural areas where small islanded grids provide a challenging environment for high penetrations of variable renewable resources. The basic breakdown and timeline of Rule 21 is as follows:

- Phase 1 (September 2017) — All new solar projects are required to use a smart inverter that complies with UL 1741-SA and provides basic grid support capabilities for inverters.

- Phase 2 (Late 2018) — Systems must include the capability to communicate with utilities using IEEE 2030.5 (SEP 2.0) protocol.

- Phase 3 (Date TBD) — Harmonizes California Rule 21 requirements with IEEE 1547 Second Edition (2018) and expands grid support requirements for voltage regulation.

Net Metering and Interconnection

Alaska has a diverse array of utilities that come in many different sizes. Utilities on Alaska’s Railbelt are the largest utilities in the state and they generate electricity using a combination of fuel sources that include diesel, natural gas, coal, wind, and hydro. Utility-scale solar may soon be a part of that mix. In the rural areas of the state, most villages generate their power using diesel generators and in some cases wind and hydro power. Because of the range of utilities and grid sizes, the way that customers can connect solar PV to the grid varies a lot from place to place. Customers should consult with their utility to see what the grid connection options are in their area. In this section common billing mechanisms for grid-tied solar PV will be described.

Net Metering on Alaska’s Railbelt

In October 2009, the Regulatory Commission of Alaska (RCA) approved net metering regulations, and the rules became effective January 15, 2010. Net metering allows grid-tied customers in participating utilities who own distributed generation such as solar or wind to subtract the energy they produce from the energy they consume on a monthly basis.

| Region | Voltage at Point of Common Coupling (% of Nominal Voltage) | Ride Through Until | Operating Mode | Maximum Trip Time |

|---|---|---|---|---|

| High Voltage 2 | V ≥ 120 | .16 Seconds |

||

| High Voltage 1 | 110 < v < 120 | 12 Seconds | Momentary Cessation | 13 Seconds |

| Near Nominal | 88 ≤ V ≤ 110 | Indefinite | Continuous Operation | N/A |

| Low Voltage | 1 70≤ V < 88 | 20 Seconds | Mandatory Operation | 21 Seconds |

| Low Voltage | 2 50 ≤ V < 70 | 10 Seconds | Mandatory Operation | 11 Seconds |

| Low Voltage 3 | V < 50 | 1 Second | Momentary Cessation | 1.5 Seconds |

| System Frequency Default Settings (Hz) | Minimum Range of Adjustability (Hz) | Ride Through Until | Ride Through Operational Mode | Maximum Trip Time (Seconds |

|---|---|---|---|---|

| f > 62 | 62-64 | No Ride Through | N/A | .16 |

| 60.5 < f ≤ 62 | 60.1-62 | 299 Seconds | Mandatory Operation | 300 |

| 58.5 ≤ f ≤ 60.5 | Not Applicable | Indefinite | Continuous Operation | N/A |

| 57.0 ≤ f < 58.5 | 57-59.9 | 299 Seconds | Mandatory Operation | 300 |

| f < 57.0 | 53-57 | No Ride Through | N/A | .16 |

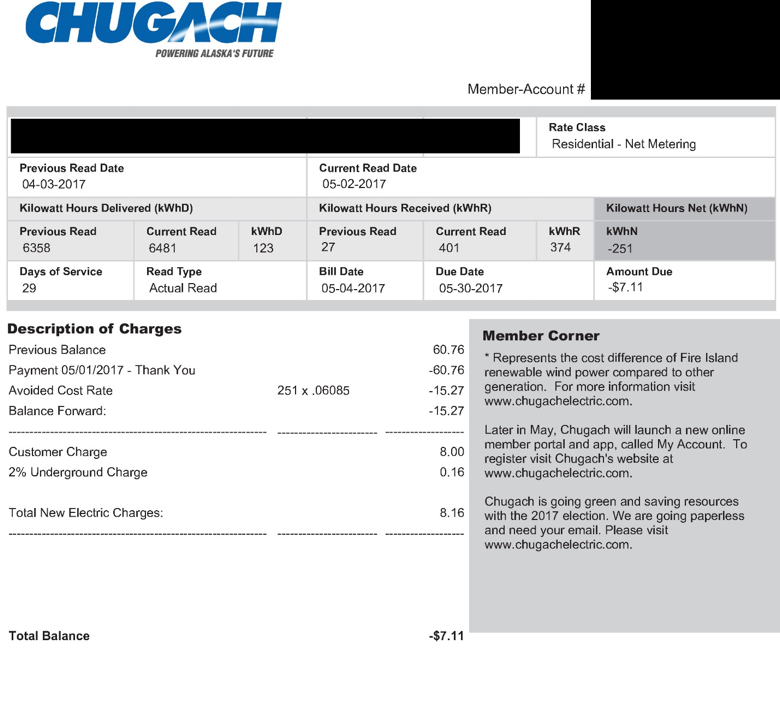

When you compare the variable output from a solar PV array to a utility customer’s varying demand for electricity, there will be times when excess electricity is generated (Gipe, 2004). For example, during a bright, sunny day the system will likely produce more electricity than the home or business is consuming at that moment and excess power will flow onto the grid. The situation will be reversed during the hours when there is no sunlight and the PV system is not producing power, and electricity will flow from the grid to the building. With net metering, a customer can essentially bank the excess electricity and consume it at a later time, when the home is consuming more than the PV system is producing. In this situation, the grid functions like a battery. Figure 15 illustrates the net metering interconnection process and shows the main components.

In Alaska, this banking of excess energy production occurs on a monthly basis. In some states it is done on an annual basis. As an example, if a customer’s solar system produces 50 kWh, but the customer consumed 100 kWh, then the customer only has to pay for 50 kWh of energy plus an interconnection fee.

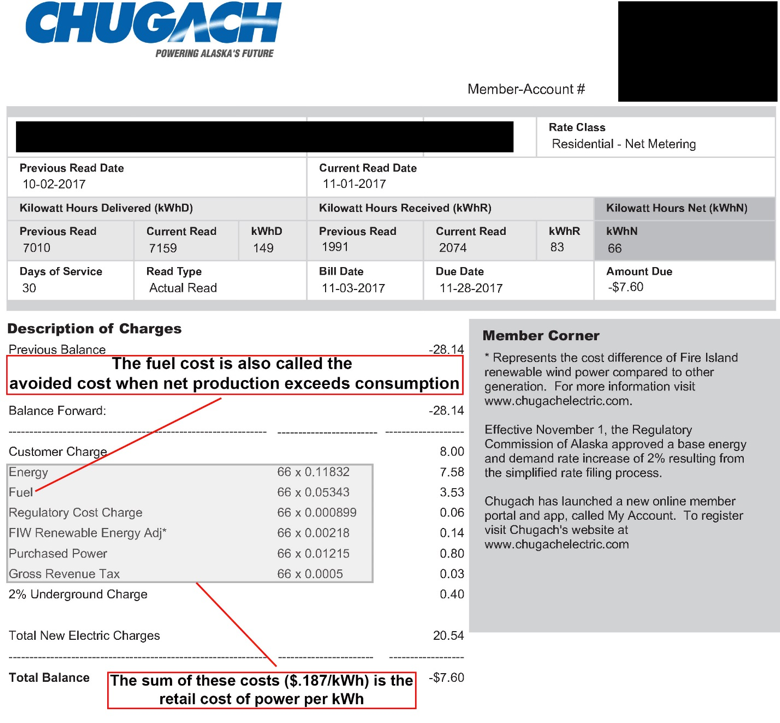

The net metering law states that any energy produced by a renewable energy system in excess of the monthly customer demand will be purchased by the utility at the avoided power cost. This rate varies by utility, but for customers in Southcentral Alaska in 2017, the avoided cost of power was generally around $.05-$.06/kWh. This is the cost of the natural gas the utility burns to produce the electricity. The rest of the cost included in the price of electricity covers the cost of infrastructure, maintenance, administrative costs, regulatory costs, and taxes. In areas of the state that burn diesel fuel to generate electricity, the avoided power cost will be significantly higher than it is in Southcentral Alaska

Net metering is an important part of the grid connected solar PV discussion because it improves the economics for these systems. Without net metering any power that flows from the customer to the utility can only be sold for the avoided power cost. Because customers are allowed to net it on a monthly basis, power produced from solar PV at any time that month, up to their total consumption can be used to offset power that they consumed, essentially valuing that power at the retail rate.

The MEA net metering website (www.mea.coop/ member-services/net-metering/) contains sample applications, FAQs, and case studies. It is an excellent resource for anyone interested in installing solar PV on their home or business.

A Net Metering Billing Example

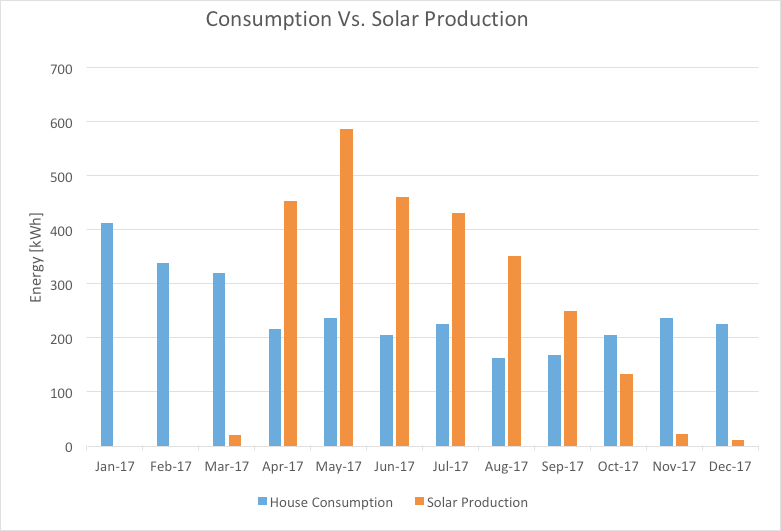

The data in Table 6 show actual monthly solar production and electricity consumption for a home with 4 kW of solar panels located in the Chugach Utility area in Anchorage for 2017. It provides a good example of net metering and billing for the year.

Table 6 shows that the solar system produced more power than the home consumed during the spring and summer months, and the homeowner was able to sell power to the utility at the avoided power cost and accumulate a credit during these months. During the fall and winter months, the homeowner purchased power from the utility. Figure 16 shows a graph of the data from Table 6. Figures 17 and 18 show the utility bills from April, when the homeowner produced more power than was consumed and received a credit from the utility, and October, when the homeowner consumed more power than their PV system produced so they had to purchase the difference from the utility.

The net metering law does not cover all regions of the state or all renewable energy systems. Renewable energy systems with a rated output of 25 kW and less are eligible for net metering. In addition, only electric utilities subject to economic regulation by the RCA are required to offer net metering. Independent systems with retail sales of less than 5,000,000 kilowatt-hours (kWh) are not required to offer net metering. Utilities can cap the allowed net metering on their systems when overall enrollment reaches 1.5% of a utility’s average retail demand for the previous year. Many of the Railbelt utilities are expected to reach this 1.5% cap in about 2021, depending on the pace of installations.

What’s Next for Net Metering in Alaska

As the number of solar PV installations has sky-rocketed over the last couple of years, the question going through many people’s minds is what will happen when the net metering cap is reached. Fortunately, Alaska doesn’t have to reinvent the wheel here since a number of states have had to renegotiate net metering laws as utilities have learned to manage the technical and economic challenges that go with high penetrations of distributed renewable energy on their grid. California, for example, has enacted time of use rates and began requiring that grid-connected solar inverters conform to updated power quality parameters. California’s new Rule 21 tariff that regulates grid-connected solar PV was described earlier in this manual.

| Month | House Consumption (kWh) | Solar Production (kWh) | Monthly Net Consumption (kWh) | Monthly Bill** | Customer Credit |

|---|---|---|---|---|---|

| Jan-17 | 413 | 0 | 413 | $82.34 |

|

| Feb-17 | 339 | 0 | 339 | $69.02 | |

| Mar-17 | 321 | 20 | 301 | $62.18 | |

| Apr-17 | 216 | 454 | -238 | $(5.09) | $5.09 |

| May-17 | 237 | 587 | -350 | $(16.34) | $16.34 |

| Jun-17 | 206 | 461 | -255 | $(22.37) | $22.37 |

| Jul-17 | 226 | 431 | -205 | $(25.64) | $25.64 |

| Aug-17 | 163 | 351 | -188 | $(27.98) | $27.98 |

| Sep-17 | 168 | 249 | -81 | $(24.44) | $24.44 |

| Oct-17 | 205 | 133 | 72 | $(3.48) | $3.48 |

| Nov-17 | 236 | 22 | 214 | $43.05 | |

| Dec-17 | 225 | 10 | 215 | $46.70 |

Assumptions for all bills:

- $.18/kWh retail cost of energy

- $8.00 monthly customer charge

- $.055/kWh avoided power cost

Solar PV Economics and Financing

Dramatic reductions in the cost of solar panels over the last decade have made solar power projects feasible in a wide array of applications on the Railbelt. This cost decrease along with the increase in solar installations is dramatically illustrated in Figure 19. In some parts of the American Southwest the cost of energy produced from solar is lower than the cost from energy produced with fossil fuels. As costs of solar panels and the associated components continue to fall and technology improves, it is likely that this trend will continue to spread.

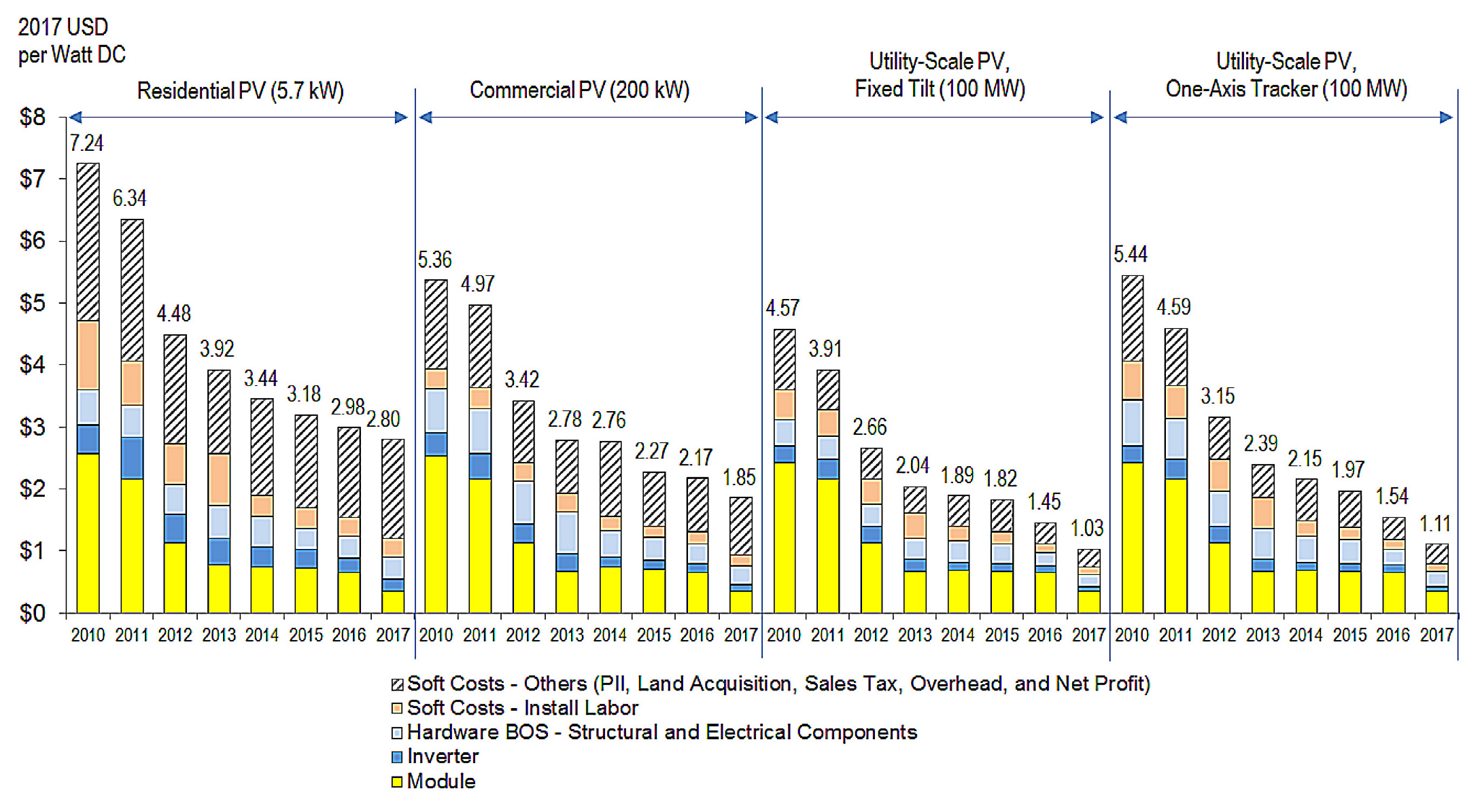

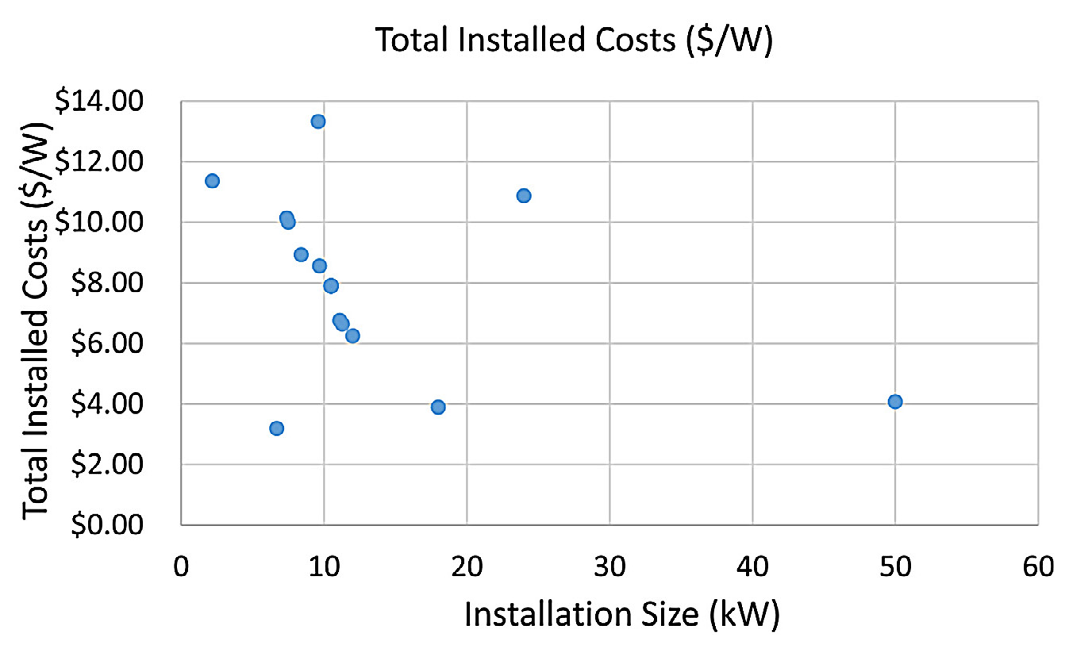

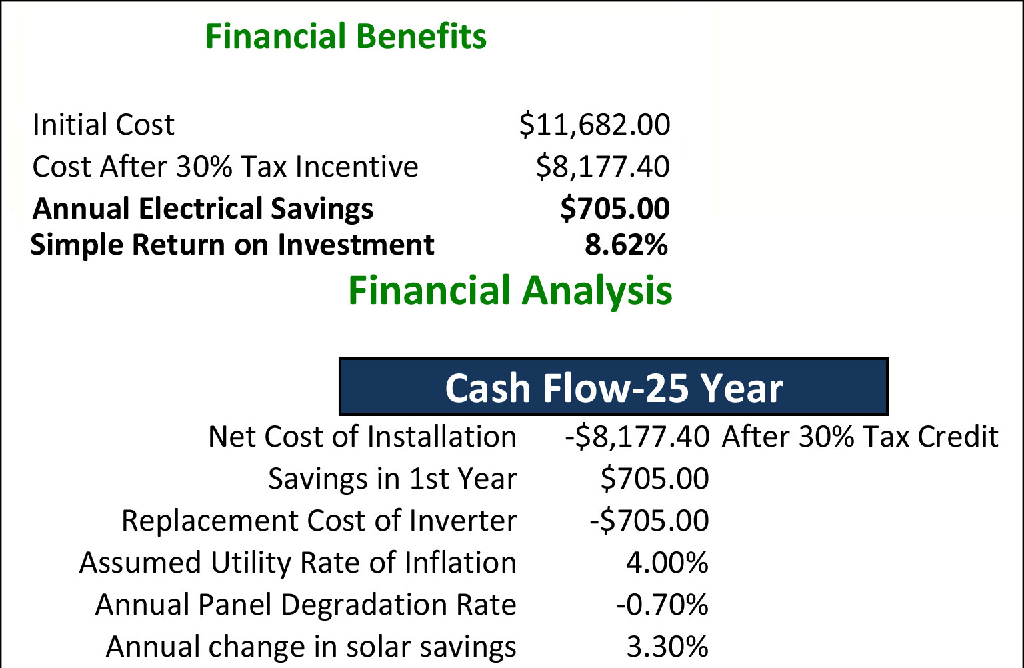

While the PV panels themselves represent the largest reduction in cost for solar technologies, the cost of other components has fallen. Figure 18 shows how the cost of each component of a solar PV system has fallen since 2010. While the costs in Alaska are not as low as those shown in Figure 20, they will undoubtedly continue to fall. As a general reference, the installation cost for residential rooftop solar in Anchorage is about $3.30/W, while the costs for an equivalent system in rural Alaska would likely run about $5.50/W because of the higher cost of shipping and labor. For a larger, utility-scale system about 500 kW in size the cost would be about $2/W for materials and installation on the Railbelt.

Considerations for solar development in rural Alaska communities receiving Power Cost Equalization

Cady Lister, Alaska Energy Authority

Like all intermittent renewable energy, solar PV energy can cause problems if not properly planned and managed when integrated into a small islanded system, such as those that exist in most rural communities in Alaska. For projects that are not being developed by the local utility, it is critical that developers work closely with the utility to ensure proper integration. Before deciding to move forward with a solar project be sure to call your local utility to find out what rules the utility has about distributed generation on the community power system. For example, a utility may have project size limitations and technical requirements for solar PV generation that is connected to the grid.